Do-it-yourself LED table lamp. How to make a lamp from LEDs with your own hands? Mounting and installation

Gradually, lighting devices are moving to LED lamp. This did not happen immediately, there was a protracted transitional period with the use of so-called housekeepers - compact gas-discharge light bulbs with a built-in power supply (driver) and a standard E27 or E14 cartridge.

Such lamps are widely used today, since their cost in comparison with LED light sources is not so "biting".

With a good balance of price and economy (price difference with conventional lamps incandescent over time pays off by saving electricity), gas-discharge light sources have a number of disadvantages:

- The service life is lower than that of incandescent lamps.

- High frequency interference from the power supply.

- Lamps do not like frequent switching on and off.

- Gradual decrease in brightness.

- Effects on nearby surfaces: A dark spot develops over time on the surface of the ceiling (above the lamp).

- And in general, I don’t really want to have a flask with a certain amount of mercury in the house.

Great alternative - LED lights. The list of advantages is weighty: - Amazing efficiency (up to 10 times compared to incandescent lamps).

- Huge service life.

- Perfect and safe power supplies (drivers).

- Absolutely independent of the number of inclusions.

- With normal cooling, they do not lose brightness for almost the entire period of operation.

- Complete mechanical safety (even if the decorative diffuser is broken, no harmful substances will enter the room).

- The directivity of the light flux makes high demands on the design of the diffuser.

- Still, they are expensive (we are talking about quality brands, nameless mid-range products are quite affordable).

But it is precisely in this construction that the “ambush” lies.

Before us is a high-quality (at the same time relatively inexpensive) lamp with a luminous brightness of 1000 Lm (equivalent to a 100-watt incandescent lamp), and a power consumption of 13 watts. I have such LED light sources that work for many years, they shine with a pleasant warm light (temperature 2700 K), and no degradation of brightness is observed over time.

But for powerful light, serious cooling is required. Therefore, the body of this lamp for 2/3 consists of a radiator. It is plastic, does not spoil appearance, and is quite effective. It follows from the design main disadvantage– the real light source is the hemisphere at the top of the lamp. This makes it difficult to select a lamp - not in every carob chandelier such a lamp will look harmonious.

There is only one way out - to buy ready-made LED lamp and, the configuration of which was originally designed for specific light sources.

The key word is buy. And what to do with your favorite floor lamps, chandeliers and other lamps in the apartment?

Therefore, it was decided to design LED lamps independently.

The main criterion is cost minimization.There are two main directions in the development of LED light sources:

1. The use of low-power (up to 0.5 W) LEDs. They require a lot, you can configure any shape. A powerful radiator is not needed (they heat up a little). A significant drawback is a more painstaking assembly.

2. Use of powerful (1 W - 5 W) LED elements. Efficiency is high, labor costs are many times less. But point radiation requires the selection of a diffuser, and good radiators are needed to implement the project.

For experimental designs, I chose the first option. The most inexpensive "raw material": 5 mm LEDs with a dispersion of 120 ° in a transparent case. They are called "straw hat".

The characteristics are as follows:

- forward current = 20 mA (0.02 A)

- voltage drop across 1 diode = 3.2-3.4 volts

- color - warm white

I bought several packs 100 pcs. on aliexpress(link to purchase). It cost a little less than 1 p. a piece.

As power supplies (more precisely, current sources), I decided to use a proven circuit with a quenching (ballast) capacitor. The advantages of such a driver are extreme cheapness and minimal energy consumption. Since there is no PWM controller, or a linear current stabilizer, excess energy does not go into the atmosphere: in this circuit there are no elements with a heat-dissipating radiator.

The disadvantage is the lack of current stabilization. That is, with an unstable mains voltage, the brightness of the glow will change. I have exactly 220 (+/- 2 volts) in my outlet, so this circuit is just right.

The element base is also not expensive.

- diode bridges of the KTS405A series (you can use any diodes, even Schottky)

- film capacitors with a voltage of 630 volts (with a margin)

- 1-2 watt resistors

- electrolytic capacitors 47 mF at 400 volts (you can take a larger capacity, but this is beyond the scope of economy)

- little things like a breadboard and fuses are usually in the arsenal of any radio amateur

After carefully (on the street!) Extraction of the flask with mercury vapor, there remains an excellent blank for creativity.

The basis of the fundamentals - the calculation and principle of operation of a current driver with a quenching capacitor

A typical diagram is shown in the illustration:

How the circuit works:

Resistor R1 limits the current surge when power is applied until the circuit stabilizes (about 1 second). Value from 50 to 150 ohms. Power 2 W.Resistor R2 ensures the operation of the ballast capacitor. First, it discharges it when the power is turned off. At a minimum, so that you are not shaken by current when unscrewing the light bulb. The second task is to prevent a current surge in the case when the polarity of the charged capacitor and the first half-wave of 220 volts do not match.

Actually, the quenching capacitor C1 is the basis of the circuit. It is a kind of current filter. By selecting the capacitance, you can set any current in the circuit. For our diodes, it should not exceed 20 mA at the peak values of the mains voltage.

Next, the diode bridge works (after all, LEDs are elements with polarity).

An electrolytic capacitor C2 is needed to prevent the lamp from flickering. LEDs have no inertia when turned on and off. Therefore, the eye will see a flicker at a frequency of 50 Hz. By the way, cheap Chinese lamps sin with this. The quality of the capacitor is checked using any digital camera, even a smartphone. Looking at the burning diodes through the digital matrix, you can see blinking, indistinguishable to the human eye.

In addition, this electrolyte gives an unexpected bonus: the lamps do not turn off immediately, but with a noble slow attenuation until the capacity is discharged.

The calculation of the quenching capacitor is made according to the formula:

I = 200*C*(1.41*U network - U led)

I - received circuit current in amperes

200 is a constant (network frequency 50Hz * 4)

1.41 - constant

C - capacitance of capacitor C1 (quenching) in farads

U network - the estimated voltage of the network (ideally - 220 volts)

U led - the total voltage drop across the LEDs (in our case - 3.3 volts, multiplied by the number of LED elements)

By selecting the number of LEDs (with a known voltage drop) and the capacitance of the quenching capacitor, it is necessary to achieve the required current. It should not be higher than that specified in the characteristics of the LEDs. It is the current strength that you adjust the brightness of the glow, and inversely proportional to the life of the LEDs.

For convenience, you can create a formula in Excel.

The circuit has been tested repeatedly, the first copy was assembled almost 3 years ago, it works in a lamp in the kitchen, there were no malfunctions.

Let's move on to the practical implementation of projects. There is no point in discussing the number of LED elements and the capacitance of the capacitor in separate circuits: the projects are individual for each lamp. Calculated strictly according to the formula. The above circuit for 60 LEDs with a 68 microfarad capacitor is not just an example, but a real calculation for a current in the circuit of 15 mA (to extend the life of the lights).

LED lamp in carob chandelier

We use the gutted cartridge from the housekeeper as a case for the circuit and the supporting structure. In this project, I did not use a breadboard, I assembled the driver on a 1 mm thick PVC round. It turned out just the right size. Two capacitors - due to the selection of capacitance: the required number of microfarads was not found in one element.

A jar of yogurt was used as a housing for placing LED elements. In the design, I also used 3 mm PVC foam sheet trimmings.

After assembly, it turned out neat and even beautiful. This arrangement of the cartridge is associated with the shape of the chandelier: the horns are directed upwards, towards the ceiling.

Next, we place the LEDs: according to the scheme, 150 pcs. We pierce the plastic with an awl, labor costs: one full evening.

Looking ahead, I will say: the case material did not justify itself, it is too thin. The next lamp was made of 1 mm PVC sheet. To give shape, I calculated the sweep of the cone for the same 150 diodes.

It turned out not so elegant, but it is reliable, and it keeps its shape perfectly. The lamp is completely hidden in the chandelier's horn, so appearance is not so important.

Actually, installation.

It shines evenly, does not hit the eyes.

I did not measure lumens, it feels like it is brighter than a 40 W incandescent lamp, a little weaker than 60 W.

LED lamp in a flat ceiling lamp for the kitchen

An ideal donor for such a project. All LEDs will be located in the same plane.

We draw a template, cut out a matrix to place LED elements. With this diameter, a flat PVC sheet will deform. Therefore, I used the bottom of a plastic bucket from under construction mixtures. There is a stiffening rib along the outer contour.

Diodes are installed using the usual awl: 2 holes for marking.

According to statistics, it was found that the cost of LED lamps has dropped significantly. Such indicators led to an increase in the purchase of highly economical lighting equipment for private houses and apartments. Those who are excellent with a soldering iron will not need to go to the store at all in order to equip their home, as you can create a lamp with your own hands, without resorting to factory products. Thus, you can save a large amount of money and choose the design of the device that will fit the interior of the apartment.

Scheme of the LED lamp.

LEDs have their own peculiarity, which consists in the mode of operation direct current and low voltage. Therefore, for the implementation of the lighting process, devices such as power supplies are mainly used. Some people solder electrical circuits on boards on their own, which is not so easy, especially for those who are not familiar with this field of activity.

When creating a lamp with your own hands, a lamp or any other lighting device, you need to take into account the fact that one third of such a unit as the rated power will be spent on converting the luminous flux, while the rest of the parts are needed for heat loss.

It is important to remember that overheating of the LEDs may shorten their life. When assembling any design of LEDs on your own, heat must be removed from the entire structure during power supply.

What LEDs should you use?

Table of types of LEDs.

Initially, it is advisable to choose the specific type of LEDs that you need. If we consider powerful and low-power ones, then the first type is much more profitable, due to the fact that the labor intensity is higher. The ratio of low-power to high-power is 20:1. According to such indicators, we can conclude that with low-power LEDs there is much more soldering. Among the powerful LEDs, there are a couple of varieties, some of which are designed for output installation work, while others are for surface. In most cases, output is used, since with them installation work carried out much faster.

Power supplies

For the durability of LEDs, an excellent driver is needed, and in another way it can be called a power source. The driver can be packaged or unpackaged, with or without galvanic isolation. If we consider exactly the alteration of lamps, then it is desirable to use the type of unpackaged driver, in which there is galvanic isolation.

The caseless view is very useful in that it is compact in size and also has a lower degree of heating. But there are certain disadvantages, which are manifested in the difficulty of fastening.

The use of galvanic isolation is generally required for safety reasons, as this can avoid electric shock. In the absence of such technology, some receive minimal electrical shocks.

The electrical circuit of the LED lamp.

When choosing drivers, it is advisable to pay attention to the indication of the minimum and maximum number of LEDs that can be connected to the connection. If such data is not available, then it is worth looking at the output voltage indicators of the power supply.

The power supply can be of two types, one of which consists of an electromagnetic interference filter, and the second, respectively, does not have it. Devices that do not have filters are more likely to interfere with electromagnetic waves and conduct frequencies to receivers.

Using a heatsink for LEDs

In order to use the LED successfully and for a long time, it is worth using heat sinks, as they are as important components of the process as power supplies. The radiator must be made exclusively of aluminum. Finding such material is very simple, since each person has old aluminum dishes. In order to be able to dissipate heat from the LED, it is the size of the area that must be taken into account, and not the thickness. It is worth noting that fans are installed on computer coolers, since without such a device, heat from the LED will be removed at a minimum speed.

The process of making a lamp with your own hands

Before you start developing a lamp yourself, it is advisable to prepare everything necessary tools. In particular, it is desirable to have:

Diagram of the lamp body.

- basic and spare LEDs;

- microtransformer;

- multimeter;

- red LED lights;

- 100 ohm resistor;

- a 400 uF and 10 uF capacitor;

- cartridge;

- degreaser;

- soldering iron;

- mounting adhesive;

- board;

- lampshade.

Initially, it is desirable to check each LED that will be included in the circuit, and the quality of the supply voltage in network cable. To carry out such a process, it is worth using a microtransformer. Thus, when setting up and during a test check of a future lighting device, the adjustment will be much smoother.

In order to measure whether the voltage drops with direct current and the effect on the resistor or not, and a multimeter is used to accurately calculate the current of the diodes. As a rule, when self-assembling, they try to use six-volt lamps, but often those that are rated for 12 volts may also be needed.

The diodes themselves must be High Quality to avoid an unpleasant bluish glow, which will not only spoil the appearance of the lamp, but also harm the eyes.

Scheme of connecting LED parts to the lamp housing.

The assembly scheme can be called very simple and without loss for the driver. The only drawback is the lack of insulation on the wires, that is, the LED lamp itself can be subject to current shocks. Focusing on the latest data, it should be borne in mind that it is desirable to protect the lamp from falling, but later the circuit can be upgraded.

- Resistors are needed to protect the board when connected to the network in order to avoid a voltage surge. In its absence, the use of a tiny rectifier bridge is desirable.

- The use of a 400uF capacitor is required in order to set the energy at the right level, which is required for transmission and additional addition of lamps, with free bandwidth. Before work, it is advisable to make sure that it is the type of rated voltage that is being used, which, as a rule, is half the usual current in the network.

- The use of a 10 uF capacitor is necessary to create an ideal light source, as well as to eliminate effects such as glare and flashing. The height of the rated voltage in this case should be twice as high as the previous capacitor.

If it is not possible to purchase a new cartridge, it can be removed from the old lamp. To do this, you need to carefully break the light bulb, and so that the socket part of the cartridge is not damaged. After such a procedure, the cartridge itself should be protected and treated with a degreaser. It is important that before installation, the hole in the cartridge is checked again for the presence of lamp residues that can harm the future lighting system, and it is advisable to carry out additional processing with acetone or alcohol.

Mounting the cartridge to the resistor and transistor

Next up is the soldering work. Using a soldering iron, a tiny rectifier is installed, and the materials must be prepared in advance and be at hand. The surface is processed in a mandatory mode, and the actions themselves must be as accurate and accurate as possible in order to prevent damage to already installed parts.

In order to carry out heat shrinkage, any type of mounting adhesive is used, since the material must be intended for such actions, and in no case for clerical purposes.

Installation of LED lamps is considered the most important and interesting point in the entire assembly of the lamp. The basis will be a board purchased in advance or prepared from old appliances. If it belonged to old structures, then, accordingly, the board should be cleaned of parts and various burrs.

When conducting and connecting each contact, they should be checked and cleaned if the signal is not received. There is very little left - and the lamp will be able to please its creator. In order to complete the work, you simply need to collect all the details that are available. To be more precise, each part is soldered to the tablet and to the resistor device. Next, everything is isolated with glue, the connections between the diodes are checked for proper light propagation.

Due to their numerous positive qualities, reliability, practicality, LED lamps have conquered the market almost from the first moments of their appearance. Lamps with LED light sources have a long service life, do not heat up during operation, consume a minimum amount of energy with a high power dissipation of the emitted light flux. The peculiarity of the operation of LEDs is associated with the manufacturing technology of the p-n junction, the choice of a crystal. Modern technologies make it possible to produce very bright LEDs with a luminous flux of 4000 K, which is much more than even economical fluorescent lamps can emit.

Lamps are available with a yellow or white glow, so buyers can choose the most suitable light sources for their premises. Yellow, having a glow temperature of 6000 K, create a warm glow, and white with 4000 K - cold.

LED bulbs are more cost effective than incandescent or "energy saving" bulbs, but due to manufacturing features, their constructive complexity, they are more expensive. Although, comparing the design and manufacturability of luminescent light sources, we can conclude that the production of LEDs is easier.

Given the high price of LED lamps, many people want to make it with their own hands, especially for this all the necessary parts can be purchased on the radio market. What can't you say about the mercury lamp, in which not only the power board is complicated, but also the gas flask is an inaccessible element. Therefore, if you want to make high-quality LED lamps for the greenhouse with your own hands, then this can be done quite simply.

Gallery: DIY LED lamps (25 photos)

Scope of application

The advantage of LED light sources lies in their versatility. Manufacturers produce different LED matrices or LEDs themselves in terms of radiation power, shape and number of elements. Therefore, you can design lamps at your discretion, both on a standard base from a broken lamp, and on a specialized one in accordance with the requirements for connecting to a driver or control board.

The advantage of LED light sources is the controllability of the brightness of the glow by changing the voltage at its input. Thus, you can get a shade from barely noticeable to overly bright. This property allows you to create many useful things:

Moon Phase Sourdough: Tips and Recipes

LEDs have been used in many areas due to their practical qualities. They are actively used in industry, everyday life, medicine, preschool institutions.

DIY manufacturing

Many different forms of lamps and lighting systems are known, which can be made by hand in a case, or maybe finished tape used which is also very convenient. For example, when creating a backlight for a keyboard or shelves in a closet.

What will be required to make a LED lamp? You don’t have to think long, because LED light sources are universal. They can be connected to AC or DC voltage of any rating. Enough to make quality driver or control unit and correctly position the LEDs on the plate.

Mounting and installation

Before proceeding with the manufacture of an LED lamp, it is worth considering its purpose. If it is installed in a standard cartridge, then this will require an E27, E14, G9 base. You can take it from any old light bulb, for example, from a fluorescent one. Exactly the same principle is followed when lighting a greenhouse with LED lamps.

Depending on the purpose, LED lamps can also be different. Some are designed for general lighting, for use as nightlights or as a phytolamp for growing plants. In the first case for the manufacture of lamps bright LEDs of a cold or warm glow are used, which is most preferable. From the point of view of the impact on human vision, it is better to buy lamps with a yellow glow, the same applies to the choice of the LEDs themselves.

And when it comes to a night light or a dim backlight, then for its manufacture you should choose colors other than white or use glow modes with low brightness. If it is to be make a phytolamp for growing plants, it is better to choose the red and blue colors of the light flux. It is the spectrum of these shades that has a beneficial effect on growth and ensures the intensive development of plants.

How to make a phytolamp

LED lamps are widely used, especially often they are used for growing plants in greenhouses. For this, the so-called phytolamp is used. Its peculiarity lies in the spectrum of light. Plants grow well in red, blue and yellow shades of light. For example, red promotes better photosynthesis, blue stimulates the intensity of growth at the cellular level, and yellow enriches the plant with other important components. Therefore, do-it-yourself LED lamps will be an ideal option, especially when it comes to growing plants.

How many square meters in 1 acre of land

But in order for the plant to really intensively grow in the greenhouse, strengthen and form faster, it is necessary to maintain the proportion of the amount of red light to blue in a ratio of 1:3. And add some yellow. plant under these conditions much stronger, stronger and healthier. Therefore, if you decide to grow seedlings, then you can make a phytolamp with your own hands. To do this, you will need to buy a tape or combine the red and blue colors of the LEDs in the lamps for the greenhouse. Such lighting in a greenhouse will not require significant material waste, because the price of materials is lower than that of a finished phytolamp.

Thanks to the ability to place lighting sources in any convenient place, you can save on electricity. For example, the tape can be stretched over the plants themselves, eliminating unnecessary waste of lighting the space of the entire greenhouse.

For the manufacture of the lamp, you do not need to buy special LEDs; market or ordered from an online store are quite suitable for greenhouses. On sale there are various models, it is important that the brightness is sufficient, and the color corresponds to the effective spectrum.

Basic design

When it comes to making DIY LED lighting for greenhouses or for other specific needs, the type of design is selected based on the features of its fastening. If to be installed into a standard pendant lamp with an E27 cartridge, then, accordingly, it is better to use a standard base.

When it comes to making DIY LED lighting for greenhouses or for other specific needs, the type of design is selected based on the features of its fastening. If to be installed into a standard pendant lamp with an E27 cartridge, then, accordingly, it is better to use a standard base.

The light bulb body can be made from any transparent material. But you will get the best effect from the direct glow without the use of various filters. But flasks and diffusers that's exactly what they are. When it comes to making a lamp for household needs, beauty can be put aside.

Power Supply Selection

LED light sources are versatile. They can be connected to any supply voltage. But only for the implementation of this it will be necessary to make required driver or simple power supply, the design of the device should be selected based on the location of the lighting arrangement. There is almost always high humidity in the greenhouse, so the power supply must be sealed.

LED light sources are versatile. They can be connected to any supply voltage. But only for the implementation of this it will be necessary to make required driver or simple power supply, the design of the device should be selected based on the location of the lighting arrangement. There is almost always high humidity in the greenhouse, so the power supply must be sealed.

In practice, there are many schemes for connecting LEDs in the manufacture of do-it-yourself greenhouse lighting with power from the mains. constant voltage 12V, and to a 220V network with alternating current. But the formats of the supply circuits do not end there, because any voltage can be used by standard calculations.

How to calculate the power supply

To choose the right components and select the correct modes of operation of the light source for a greenhouse or other place, you need to know the parameters of the LEDs. And these include:

- Supply voltage with direct connection. Almost all LEDs, if it is not an assembly, have a standard supply voltage of 3 V.

- Current consumption at direct connection. A standard p-n junction for normal glow consumes 20-30 mA. But there are also LEDs with an increased current of up to 100 mA or more, called super-bright. Therefore, it is important to check the parameters in the reference literature, since it is available without restrictions on many portals.

- Peak current and voltage. These values are indirect, but important when calculating a quality and reliable source.

Consider an example of calculating a power source for a lamp for 20 LEDs connected in series-parallel. The first thing to do is to make a reservation. If want to make really reliable light source, then you need to add to the circuit:

- Varistor with a pulse voltage of 278 V, provided that a 220 V circuit is connected.

- Electronic fuse, it will protect the device from overcurrent in case of burnout of one of the LEDs on the short circuit.

- Stabilizer. To increase the reliability of the luminaire, a stabilizer of 3V or more should be included in its circuit, depending on the total voltage of the series connection of the LEDs. There are 10 of them in the lamp under consideration, so the stabilization voltage should be 30 V.

Practical implementation

In practice, the driver circuit is greatly simplified, excluding all kinds of protections and fuses. Therefore, it is difficult to call high-quality finished lamps. But this is not always the case. Expensive LED lamps are equipped with a really reliable source with all the protections.

Devices with isolation capacitor

The most common and practical power supply scheme for LEDs is precisely capacitive source. It takes up little space and does not require many professional skills to manufacture.

The most common and practical power supply scheme for LEDs is precisely capacitive source. It takes up little space and does not require many professional skills to manufacture.

The figure previously depicted the classic scheme of a traditional feeder. It has a decoupling capacitor, a discharge resistor, a rectifier and a zener diode. It is not recommended to connect the circuit without load, because amplitude value voltage will be high and if one of the LED circuits breaks, the zener diode will fail.

Driver on PWM controller

More durable and high-quality are circuits with a driver on a microcontroller and a transformer. His scheme presented in the picture above. It also does not require many details, and the order of calculation can be found in the description. Everything is implemented quite simply.

A 220 volt LED lamp saves 1.5-2 times more electricity than a fluorescent lamp, and 10 times more than an incandescent lamp. In addition, when assembling from a burnt-out lamp, the cost of manufacturing such a lamp will be much lower. A do-it-yourself LED lamp is assembled quite simply, although you can only work with high voltage if you have the appropriate qualifications.

Advantages of a homemade lamp

In the store you can find many types of lamps. Each type has its own disadvantage and advantage. Incandescent lamps are gradually losing ground due to high energy consumption, low light output, despite a high color rendering index. Compared to them, fluorescent light sources are a real miracle. Energy-saving lamps - their more modern modernization, which made it possible to use the advantages of fluorescent light in the most common lamps, with E27 socles, devoid of the unpleasant flicker of the old representatives of this family.

But fluorescent lamps also have disadvantages. They quickly fail due to frequent switching on and off, moreover, the vapors contained in the tubes are poisonous, and the design itself requires special disposal. Compared to them, the light-emitting diode (LED) lamp is the second revolution in lighting. They are even more economical, do not require special disposal and last 5-10 times longer.

LED lamps have one, but a significant drawback - they are the most expensive. To reduce this minus to a minimum or turn it into a plus, you will need to build it from an LED strip with your own hands. At the same time, the cost of the light source becomes lower than that of luminescent counterparts.

Homemade LED lamp has several advantages:

- the service life of the device with proper assembly is a record 100,000 hours;

- in terms of watt / lumen efficiency, they also surpass all analogues;

- the cost of a homemade lamp is not higher than that of a fluorescent lamp.

Of course, there is one drawback - the lack of guarantees for the product, which must be compensated by the exact observance of instructions and the skill of an electrician.

Assembly materials

There are a lot of ways to create a lamp with your own hands. The most common methods are using an old base from a burnt out fluorescent lamp. Everyone in the house will find such a resource, so there will be no problems with the search. In addition, you will need:

- Base from a burnt product.

- Directly LED. They are sold as LED strips or individual LEDs NK6. Each element has a current strength of approximately 100–120 mA and a voltage of approximately 3–3.3 Volts.

- You will need a diode bridge or 1N4007 rectifier diodes.

- You need a fuse, which can be found in the base of a blown lamp.

- Capacitor. Its capacitance, voltage and other parameters are selected depending on electrical circuit for the assembly and the number of LEDs in it.

- In most cases, you will need a frame on which the LEDs will be attached. The frame can be made of plastic or similar material. The main requirement is that it should not be metallic, conductive and should be heat resistant.

- To securely attach the LEDs to the frame, you will need superglue or liquid nails (the latter is preferable).

One or two elements from the above list may not be useful in some schemes, in other cases, on the contrary, new chain links (drivers, electrolytes) may be added. Therefore, the list of necessary materials must be compiled in each case individually.

We collect a lamp from an LED strip

We will analyze step by step the creation of a 220 V light source from an LED strip. To decide to use the innovation in the kitchen, it is enough to remember that self-assembled LED lamps are significantly more profitable than fluorescent counterparts. They live 10 times longer and consume 2-3 times less energy at the same light level.

- For construction, you will need two burned-out fluorescent lamps half a meter long and 13 watts. There is no point in buying new ones, it is better to find old and non-working ones, but not broken and without cracks.

- Next, we go to the store and buy an LED strip. The choice is large, so approach the purchase responsibly. It is advisable to buy tapes with pure white or natural light, it does not change the shades of surrounding objects. In such tapes, LEDs are assembled in groups of 3 pieces. The voltage of one group is 12 volts, and the power is 14 watts per meter tape.

- Then you need to disassemble the fluorescent lamps into their component parts. Carefully! Do not damage the wires, and do not break the tube, otherwise the toxic fumes will escape and you will have to clean up, as after a broken mercury thermometer. Do not throw away the extracted insides, they will come in handy in the future.

Below is a diagram of the LED strip we bought. In it, LEDs are connected in parallel, 3 pieces in a group. Please note that this scheme does not suit us.

Below is a diagram of the LED strip we bought. In it, LEDs are connected in parallel, 3 pieces in a group. Please note that this scheme does not suit us.

- Therefore, you need to cut the tape into sections of 3 diodes each and get expensive and useless converters. It is more convenient to cut the tape with wire cutters or large and strong scissors. After soldering the wires, the diagram below should be obtained.

The result should be 66 LEDs or 22 groups of 3 LEDs each, connected in parallel along the entire length. The calculations are simple. Since we need to convert alternating current to direct current, the standard voltage of 220 volts in the electrical network must be increased to 250. The need to "throw" the voltage is associated with the rectification process.

The result should be 66 LEDs or 22 groups of 3 LEDs each, connected in parallel along the entire length. The calculations are simple. Since we need to convert alternating current to direct current, the standard voltage of 220 volts in the electrical network must be increased to 250. The need to "throw" the voltage is associated with the rectification process. - To find out the number of sections of LEDs, you need to divide 250 Volts by 12 Volts (voltage for one group of 3 pieces). As a result, we get 20.8 (3), rounding up, we get 21 groups. Here it is desirable to add another group, since the total number of LEDs will have to be divided into 2 lamps, and this requires an even number. In addition, by adding another section, we will make the overall scheme safer.

- We will need a DC rectifier, which is why you can not throw away the removed insides of a fluorescent lamp. To do this, we take out the converter, with the help of wire cutters we remove the capacitor from the common circuit. It is quite simple to do this, since it is located separately from the diodes, it is enough to break off the board.

The diagram shows what should happen in the end, in more detail.

The diagram shows what should happen in the end, in more detail.

- Next, using soldering and superglue, you need to assemble the entire structure. Don't even try to fit all 22 sections into one fixture. It was said above that you need to specifically find 2 half-meter lamps, since it is simply impossible to place all the LEDs in one. Also, you do not need to rely on a self-adhesive layer on the back of the tape. It will not last long, so the LEDs need to be fixed with superglue or liquid nails.

Let's summarize and find out the advantages of the assembled product:

- The amount of light from the resulting LED lamps is 1.5 times greater than that of fluorescent counterparts.

- The power consumption is much less than that of fluorescent lamps.

- The assembled light source will serve 5-10 times longer.

- Finally, the last advantage is the directivity of the light. It does not scatter and is directed strictly downwards, thanks to which it is used at the desktop or in the kitchen.

Of course, the emitted light is not very bright, but the main advantage is the low power consumption of the lamp. Even if you turn it on and never turn it off, it will consume only 4 kW of energy in a year. At the same time, the cost of electricity consumed per year is comparable to the cost of a ticket in a city bus. Therefore, it is especially effective to use such light sources where constant illumination is required (corridor, street, utility room).

We collect a simple light bulb from LEDs

Let's take a look at another way to create an LED lamp. A chandelier or table lamp needs a standard E14 or E27 base. Accordingly, the circuit and the diodes used will be different. Compact fluorescent lamps are now widely used. We need one burned out cartridge, we will also change the general list of materials for assembly.

You will need:

- burnt base E27;

- RLD2-1 driver;

- NK6 LEDs;

- a piece of cardboard, but plastic is better;

- Super glue;

- electrical wiring;

- as well as scissors, soldering iron, pliers and other tools.

Let's start creating a homemade lamp:

The luminous flux of the assembled lamp is 100–120 lumens. Pure white light makes the bulb appear significantly brighter. This is enough to illuminate a small room (corridor, utility room). The main advantage of the LED light source is low power consumption and power - only 3 watts. Which is 10 times less than incandescent lamps and 2-3 times less than fluorescent ones. It works from a conventional cartridge powered by 220 volts.

Conclusion

So, having idle linear or compact fluorescent lamps at hand and a few elements listed above in this article, you can create an LED lamp with your own hands, which has a number of advantages. One of the main ones is low cost compared to lamps that can be purchased at the store. During assembly and installation, safety measures are required, since you have to work with high voltage, so you should follow the installation sequence according to the diagram. As a result, you get a lamp that will work for a long time and please the eye.

Video

In this article, we will inspire you with various ideas for creating DIY lamps. And most importantly, we will offer light sources that are easy and convenient to arrange in the most unusual design solutions. You will not need to think about where to find the LEDs, a platform for sticking them on, soldering wires and doing other technical things. We have already thought for you and free you time for fantasies and bright ideas for decorating a lamp!

Incredible designs are realized with their own hands made of wood, metal, fabric, paper, plastic or thread. An example of creating a lamp from plastic cups:

DIY floor lamp made of paper cups and garlands.

DIY table LED lamp made of cardboard. There is a led light inside.

Antique do-it-yourself ceiling lamp.

DIY wall LED lamp made of paper (origami).

Wall LED lamp made of plywood.

The use of decorative homemade lamps

Homemade lamps perfectly perform the role of decorative lighting. They are rarely used for general lighting. For the manufacture of materials used poorly transmitting light, and light sources are limited in size or power. To avoid damage to the structure, it is recommended to use low-heating LED lamps or strips as a light source, which, unlike incandescent lamps, do not pose a fire hazard.

Homemade lamps as the main lighting

As the main lighting, homemade lamps are increasingly used due to technological, powerful and safe light sources.

Homemade lamp based on Armstrong LED lamp 595x595.

LED lamp for main lighting.

DIY ceiling lamp made of paper. safe as a light source in this design,because it doesn't get hot.

How to make your own LED lamp?

Homemade LED lamp based on Armstrong 600x600 LED panel.

A powerful alternative to steel for making do-it-yourself lamps from improvised means. Many sizes and shapes allow you to create floor, wall, ceiling or pendant luminaires of unusual design and high power. Used to repair an old lamp or to design your own unique lighting design.

for repairing and replacing an old lamp or creating a new lamp with your own hands.

LED module with temperature control and remote control remote control.

The driver and all the necessary electronics are already built into the . Unlike LED strips, the matrix (module) is connected directly to the 220 volt network. The OPPLE LED module is compact in size, well-cooled, and each LED on it is equipped with its own lens for the most even distribution of light.

Lens on each LED for the most even distribution of light.

A small 12 W module (analogue of 95 W) is suitable for decorative home-made lamps:

Decorative LED lamp made of semi-antique wood.

Do-it-yourself hanging lamp made of paper (origami kusudama).

Designed for the brightest solutions (similar to 600 W) with remote control, brightness control (built-in dimmer) and changeable light temperature from warm light (3000 K) to cold light (6000 K).

How to make a bright LED lamp from improvised materials with a control panel, brightness and light temperature adjustment from warm to cold.

It became possible to make original lamps technologically advanced and even more unusual thanks to various lighting settings. Now you can play with the temperature of the light (from yellow to white) and adjust the brightness of the light.

It is important that OPPLE LED modules have a well-thought-out cooling system and they almost do not heat up. This makes it possible to create design solutions from your favorite materials: wood lamps, paper pendant lamps, plywood wall lamps, floor lamps from improvised materials. Now it's easier than ever to create your own DIY LED lamps.

Table lamp (night light) made of wood (plywood) with your own hands.

Homemade LED (LED) lamp made of paper.

Ceiling pendant lamp in loft style made by hand.

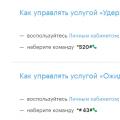

How to send I'm waiting for a call from Tele2 to another subscriber Number I'm waiting for a call

How to send I'm waiting for a call from Tele2 to another subscriber Number I'm waiting for a call Service "Waiting Call Hold" Megafon How to remove call hold on the phone

Service "Waiting Call Hold" Megafon How to remove call hold on the phone How to check favorite velcom numbers

How to check favorite velcom numbers