What is better stamps or casting. Which wheels are better - stamped, cast or forged? The difference between prefabricated alloy wheels and alloy wheels

Puzzled by the question of upgrading the basic rims to something new, prettier? Do you like passing cars on beautiful alloy wheels but you've heard a lot of cons about them. Well, let's talk about what is better: casting or stamping. Perhaps this will allow you to make a choice. To begin with, technical points and their features for each type of rims.

Wheel High Quality requires all three elements: light weight, stiffness and strength. If the rim is rigid, it will resist deformation when it is subjected to force. Although metal is considered "hard", metal tends to deform when a force is applied and return to its original shape when the force is removed. Rigidity is often confused with strength, but it is different because strength is a measure of the tendency to break. To make the most out of today's high-performance tire, the wheels must have high stiffness to maintain a proper connection between the chassis and the tires.

How is casting different from stamping?

Stamping or more correctly - steel wheels.

They are made of black rolled metal (stamped), after which they are primed and, if necessary, painted and varnished, we read about painting rims with our own hands on. For the manufacturer, such disks are easy to manufacture and not expensive. As a result, they can offer such discs to the end customer at low prices. This is their first advantage.

They are made of black rolled metal (stamped), after which they are primed and, if necessary, painted and varnished, we read about painting rims with our own hands on. For the manufacturer, such disks are easy to manufacture and not expensive. As a result, they can offer such discs to the end customer at low prices. This is their first advantage.

The material from which they are made

On the other hand, wheels with low rigidity can be easily deformed by tire loading. How can we increase the rigidity of the wheels? As long as the wheels are made of aluminum alloy, the use of a different production method does not affect the rigidity of the wheel. This is because all aluminum alloys used for forging and casting produce the same material property with the same stiffness.

Comparison of forged aluminum alloy and cast aluminum alloy. You may think that the forging process creates stronger materials. However, when forged and cast aluminum alloys are measured by Young's modulus, it is practically the same as the two methods. Forged and cast aluminum alloys are almost the same in terms of specific gravity. So if you make exactly the same shape of wheels using the forging and casting method, the weight of these wheels should be the same. What is the advantage of the forging process? This is the ability to produce higher material strength.

Now for the cons. The first is corrosion (the steel used is susceptible to it, alas!). And the second is less dynamics during acceleration (all steel discs are heavy).

Cast or alloy wheels.

They are made by casting from alloys using aluminum. Molds for casting can be used quite different, in general - there is where designers can roam. Aluminum alloys are lighter than steel, but due to the fact that aluminum alloy needs more volume than steel to create rigidity in the production of a rim, so the gain in mass is not as great as sellers claim.

They are made by casting from alloys using aluminum. Molds for casting can be used quite different, in general - there is where designers can roam. Aluminum alloys are lighter than steel, but due to the fact that aluminum alloy needs more volume than steel to create rigidity in the production of a rim, so the gain in mass is not as great as sellers claim.

Generally speaking, compared with casting, forged material is superior in yield strength and tensile strength. However, no matter how great the material strength, it cannot justify extreme weight loss. Even with sufficient strength of the material, if the wheels do not have rigidity, they cannot work properly even with high performance tires.

Let's try to justify alloy wheels!?

The alloy quickly quenched and solidified starting at the disc side, creating a thinner metal structure, greatly increasing tensile strength, yield strength and elongation. This spinning process creates a "metal flux" in the metal structure of the aluminum alloy, which is similar to the metal properties seen in the forging process.

Also, alloy wheels withstand impacts a little better than steel ones, but if they are nevertheless damaged, the chances of their recovery are much less than in situations with steel wheels. As a result, alloy wheels look very good due to their diverse appearance and the material itself, this is their main plus. And the main disadvantage is their cost, which is many times greater compared to stamped discs.

This hybrid casting and forging process gives the wheel material high strength while making the manufacturing cost more affordable than forged wheels. In addition, it gives more design freedom on the face of the wheel. Structural ability is behind the best wheels.

The answer is Enkei's Design Ability. In order to maintain high rigidity under high force, it is necessary to increase the cross-sectional area of the wheel in the opposite direction of the applied force. Unfortunately, the larger this area, the heavier the wheel will be. However, if the layout, spoke cross-sectional shape, and rim profile are designed correctly, the wheel can maintain high rigidity without. adding weight.

Conclusion.

With a description of the production and features, everything seems to be clear. Now about what to choose: stamping or casting. Here, as they say, a matter of taste and wallet. In fact, both types of discs are technologically not much different, and the owner of an ordinary car is unlikely to feel the advantages in a lower casting weight without claims for sportiness. So if you are an esthete and are ready to spend money on creating some kind of perfection for the sake of feeling satisfied with the appearance of each element of your car, alloy wheels are what you need.

Casting: which is better? This is something I have been asked many times. To properly investigate the answer, let's first look at the process of each. Forging and casting are two very different ways production. When something is cast, the material is heated above its melting point and poured into a mold where it solidifies. When something is forged, it is physically inserted into the mold, remaining solid even though it is often heated.

How do cast and stamped wheels actually behave in winter?

In other words, forgings are usually better for shackles. The basics of why are pretty simple. When you melt metal to cast it, the grain size can be expanded. When it cools to a solid, the grain structure is course and more random, reducing its strength.

Well, if the car for you is still just a means of transportation from point A to point B, and you don’t care much about it appearance so don't bother buying alloy wheels, regular steel rims for you. It is better to spend this money on an additional comfort or security system when purchasing a car, and in which case plain steel wheels can be covered with plastic caps.

But how much better is forging than casting?

This article compares one type of product made in both directions. Forged parts had 26% higher tensile strength compared to cast parts. Forged parts have a 37% higher fatigue strength resulting in six times longer fatigue life. Yield strength is a measure of how much load a brace can hold before it begins to deform. The forged parts had a 58% reduction in area when lost to failure. Cast parts only had a 6% reduction in area. This means that there will be much more deformation in the forged part before failure.

- This means you can have a stronger shackle for the weight of the bottom.

- This means that forged shackles will last longer.

- Cast iron only has 66% of the yield strength of forged steel.

The problem of choosing between steel and light alloy rims continues to cause a lot of controversy among motorists. Manufacturers add fuel to the fire by advertising their own products in every possible way for the purpose of sale. Therefore, stereotypes have formed about the characteristics of products made from different metals that do not correspond to reality. Hence the goal this material- tell how stamped, forged and alloy wheels differ, how to distinguish them from each other and which ones are better suited for different operating conditions of a car.

If you're hanging overhead from a shackle, don't you want that shackle to warn you before it fails? The following text will study the processes of plastic formation in metals, their characteristics and public Utilities in the field of industrial production. Its importance and both images as useful videos for your understanding.

The importance of these processes lies in the numerous products and forms in metal that exist and their mass production, that their high demand depends on the good mechanical characteristics that the material possesses, as well as on its great malleability and ductility.

Light alloy wheels

The name "light-alloy" was given to these products because of the properties of the materials from which they are made. This is an alloy of light metals - aluminum and magnesium, for strength and ductility, titanium and copper are added to it in small quantities. Hence the second name of such discs - titanium. There are 2 types of light alloy rims:

Features of cast and stamped wheels

Forming processes are classified according to two main variables: operating temperature and type of raw material. Refers to operation at or below room temperature. This work is done by applying more stress than the metal's original strain strength.

The main advantages of cold work are: better accuracy, lower tolerances, better surface finish, the ability to obtain the desired steering properties in the final product and greater part hardness. It is defined as the plastic deformation of a metallic material at a temperature above the recrystallization temperature. The main advantage of hot working is to obtain practically unlimited plastic deformation, which is also suitable for forming large parts, because the metal has a low yield strength and high ductility.

- cast;

- forged (pressed).

These 2 groups of products differ from each other in manufacturing technology, performance properties and cost. To understand which of them is better, you need to consider the production of discs in more detail.

This is what alloy wheels look like

Note. Sales representatives often impose on motorists the opinion that, unlike cast products, forged rims are made from incredibly strong and expensive metals, almost from platinum. In fact, this is a myth, the composition of the alloy for the manufacture of both groups of products is exactly the same. Manufacturers can slightly change the ratio of basic and additional metals in the melt at their discretion.

Resulting Benefits hot work: large changes in the shape of the workpiece, less effort and stress required to deform the material, the ability to work with metals that break down during cold working, as a rule, isotropic strength properties and, finally, there are no hardening of parts due to work processes.

This characteristic separately distinguishes between the types of processes and utilities of each of them. Within this group, there are a series of processes widely used at the industrial level, these are punching, bending and embossing. It is called metal embossing for a mechanical operation that is used to make sheet holes in metal sheets. To accomplish this task, they are used from simple manual mechanisms to complex mechanical presses of high power. In the following link, you can observe the perforation process in different sheets: stamping.

About production technology

As the name implies, cast products are made by pouring molten metal into special molds (casting method). The sequence of technological operations looks like this:

- Metals - the ingredients are placed in a furnace, melted and mixed.

- The alloy is fed to the mold and poured into it with a special ladle.

- After hardening, the workpiece is removed from the mold and moved to machining. At the same time, the structure of the rim and spokes is already formed, it remains only to remove excess material along the edges and refine the holes for the bolts, as well as balance the disc.

- The last stage is testing under certain speed and shock loads.

In this video you can see different models punching for one punching machine. The main elements of a die are a die that has the shape and dimensions of the hole to be made and a die into which the die is inserted when strongly driven by the power provided by the press through an eccentric drive, having and which provides a dry and strong impact on the sheet. , which gives a clean cut of the same.

Parts of the cutting tool: The punching cutter consists of a punch and a hydraulic press in which it is located. Punch or macho: presses the sheet to die, cutting it through the play between it and the matrix. Centering Pin: Aligns the center of the press with the center of force of the die. It is located on the upper surface of the upper matrix.

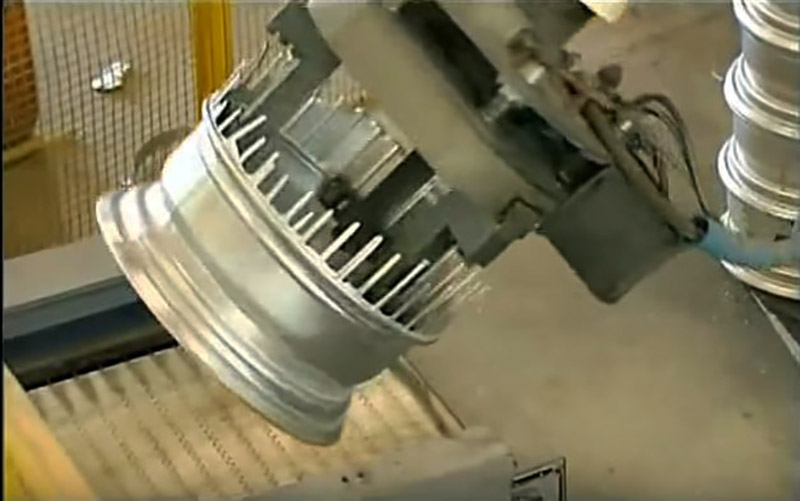

The robot moves the newly cast disc to machining

Reference. At the factories of well-known brands, the process is carried out in full automatic mode using CNC machines, even casting is performed by a robot. Manual labor is practically excluded.

Pros and cons of cast products

Coil springs around: Press the guide plate against the tape being cut so that it does not deform during cutting. Punch stepper plate or guide: This prevents the sheet from moving before punching and ensures proper positioning relative to the pulley and core.

Matrix or Female: The hardened part located at the bottom of the die. The surface of the die determines the life of the die as it has a straight part that is worn with use and must be ground to maintain good quality products. The bottom of the die serves as a structure and has a conical cavity that allows the chains to exit.

Branded forged wheels with an openwork knitting pattern

The name "forged" does not quite accurately reflect the method of production of these discs, since they are not forged, but squeezed out of a heated alloy on high-power hydraulic presses. The manufacturing algorithm is as follows:

- As in the previous case, an alloy is prepared in the furnace, from which cylindrical blanks are cast.

- Each blank goes through several pressing operations, where it is formed into a solid wheel rim without spokes and holes.

- Products undergo 2 heat treatment operations - hardening (strengthens the alloy) and tempering to relieve internal stresses in the metal.

- With the help of machining on various machines, holes are made in the disks, the spoke pattern is cut out, excess material is removed along the edges and balancing is carried out.

- Testing is carried out on special equipment under critical loads.

Note. So the second myth has been dispelled - that due to the manufacturing technology, forged wheels cannot boast of a diverse design. On CNC milling machines, any, even the most complex pattern, can be cut into the body of the workpiece.

How is casting different from stamping?

Suspension: hardened and tempered part that prevents possible indentations that occur during continuous impacts or impacts that occur during die cutting. Strap Guides: Orient the blade so it stays level for the job required.

Properties of stamped steel discs

Dies off for flowers and plants. When stamping, stamps are used in pairs. The smaller head or wedge fits into the larger head or dies. The metal to be formed, which is usually a sheet or blank cutout, is placed on a die in the printing bench. The wedge is mounted on the press piston and lowered by hydraulic or mechanical pressure.

Pros and cons of cast products

The main advantage of cast alloy wheels is their attractive appearance, which makes a car of any age and brand look much nicer. And the choice of products in terms of configuration and number of spokes is incredibly wide. This is the main reason that encourages car enthusiasts to change steel wheel rims to light alloy ones.

What gives a small wheel weight?

The simplest are drills used to drill holes in a piece. Cutting dies are used to stamp a specific shape onto metal foil for subsequent operations. Bending and bending heads are designed to perform simple or complex folds on the workpiece.

Type dies are used to create hollow shapes. To achieve a reduced area in a hollow area, such as the neck of a rifle cartridge, special reduction dies are used. When the finished part needs to have protrusions at the bottom or center, hydraulic dies are often used. In these, the wedge is replaced by a piston, which introduces pressurized water or oil into the mold, which causes the metal to bend against the die.

Other advantages also matter, but they are technical in nature:

- reduced mass of products gives less fuel consumption and increases the controllability of the car;

- for the same reason, the acceleration dynamics of the car improves, and the braking distance is reduced;

- products are initially balanced due to production technology;

- long service life.

Of the listed positive points, only the durability and balance of alloy wheels are really noticeable when the car owner changes tires in a tire shop. Improvement in handling and acceleration dynamics can only be felt by an experienced driver, and the change in fuel consumption is so insignificant that it is not noticeable at all (0.1-0.2 liters per 100 kilometers). So beauty is the priority. alloy wheels, and only then their technical parameters are valued.

It's hard to deny yourself the purchase of such beautiful wheels when there is an opportunity.

Now for the disadvantages:

- Products are afraid of strong and sharp blows. A crack appears in the thinnest place or where an air shell has formed inside the metal. Manufacturers claim that the casting cannot be repaired.

- The price of the product is higher than that of stamped steel discs. Due to the difference in prices, the difference can be from 50 to 200%.

- Cast rims should not be used on vans and light trucks as they are not designed for such loads.

- Maintenance operations for such products at a tire fitting (tire change, balancing) are more expensive.

Solder crack received from impact

Reference. In the countries of the post-Soviet space, there are many workshops where specialists have got used to soldering cracks aluminum casting. But such a repair cannot be called complete, and restored disks must not be placed on the front axle of the car.

Advantages and disadvantages of forged wheels

The essential and only drawback of forged rims is the high cost, exceeding casting by 2-5 times, depending on the manufacturer. But for this money you will receive such advantages:

- reliability and durability;

- durability, the pressed rim will last as long as the car itself;

- low weight of the product (even compared to casting), which improves the behavior of the car on the road and reduces fuel consumption.

Thanks to pressing and hardening in the manufacture of such rims, the metal does not have hidden shells and acquires increased strength, so impact cracks are extremely rare. In addition, the spokes of the product can be made thinner and more openwork, giving the wheel design additional lightness and beauty. That's what you pay money for when you buy a forged wheel.

How alloy wheels are made - video

Stamped steel rims - the secret of popularity

More than 60% of all cars in the territory of the post-Soviet countries are equipped with disks made of carbon steel sheet. The vast majority of these machines are equipped with such wheels from the factory, since they are cheaper than others. Exceptions are cars in the “luxury” configuration or elite brands for which “stamping” frankly does not fit in appearance.

Bent stampings can be rolled and aligned successfully

The most valuable advantage when driving on our roads is the high repairability of stamped discs and the ability to absorb shocks. Combined with low cost, these features make traditional iron rims the most attractive in the eyes of ordinary users. To understand how their cost is formed, it does not hurt to get acquainted with the manufacturing technology of such products.

Production by stamping

For the manufacture of iron rims, thick sheet steel is used. Workpieces of two types are cut from it - a circle and a strip, sent for further processing. The process looks like this:

- On a hydraulic press, the core of the future disk with bolt holes and technological openings is stamped from a steel circle.

- The strip is sent to the rollers, where it is bent into the shape of a cylinder. The ends of the sheet are welded together, after which the seam is cleaned.

- A hydraulic press squeezes the finished rim out of the cylinder, then a hole for the valve is drilled in it.

- Both elements are connected by welding, then covered with primer and painted.

After the impact of the press, the steel circle turns into the middle part of the rim

In the manufacture of stamped products, expensive CNC machines and furnaces are not used, which is why energy costs are significantly lower. Hence the low price of the final product.

The rim is welded to the middle part

Video of the stamping assembly process

Weaknesses of steel wheels

Compared to attractive lightweight aluminum alloy products, forged iron rims lose in appearance, which is often the reason for replacing them. Plastic decorative caps, which are always lost on the potholes of our roads, do not solve the issue, and the owner of the car has to buy new ones.

For reference. To prevent the caps from flying off the wheels, many drivers fasten them to the disks with plastic wiring clamps. This helps, although it somewhat spoils the appearance of the car.

Original Volkswagen hubcaps cost fabulous money, but are lost less often due to good fastening.

There are other negative aspects in the operation of "stampings":

- due to the large weight of the wheels, the controllability of the machine is worse, and fuel consumption is higher;

- increased stopping distance;

- stamped iron products cannot boast of good balance;

- metal rusts, and therefore requires care.

Judging by the statistics, the listed shortcomings do not bother most Russian drivers too much. Again, some of the negative points are misinterpreted by sellers. For example, the assertion that steel can rot in 2 years and the disk will become unsuitable for further use is unfounded. To bring the metal to such a state, it will take a period twice as long, and with timely care, the product will last no less than light alloy.

Note. There is a myth that the paint of stamped rims is easily scratched and quickly deteriorates, and the light alloy surface cannot be damaged. The second part of the statement is incorrect, alloy wheels can also be scratched, but it is much more difficult to paint them.

Type selection rims it is better to fulfill according to three criteria:

- depending on the operating conditions of the machine;

- class and brand of car;

- active driving in the cold or warm season.

Advice. If you expect to use one set of rims year-round, then taking into account Russian road conditions, it is better not to risk money and put a steel "stamping".

The ideal option is to have 2 sets of discs, using them in the warm and cold seasons. For summer driving on paved surfaces, light-alloy rims are perfect, but for the winter you need to put stamped ones. The problem is ice that appears on the pavement due to unremoved snow, which is why a flat road is covered with continuous potholes. The same frost along the edges of the roadway will easily scratch your beautiful titanium wheels when leaving the side of the road or approaching close to the curb.

When choosing a set of new disks, it does not hurt to take into account other recommendations:

- It is not worth shelling out and buying light alloy products if you are driving through the fields in an SUV. And vice versa, elite cars operated on flat roads should not be stamped, it looks reprehensible.

- Forged wheels are suitable for any passenger car and various driving conditions, except for frank off-road.

- Don't try to put light alloy rims on a minibus that's in commercial service, you risk ruining them quickly.

When choosing forged products, a natural question arises - how to distinguish them from casting with external similarity. After all, an unscrupulous seller can slip you a cheaper product at a price forged wheels. There are some tips for this:

- Forging is easier than casting. For example, a 15-inch forged rim weighs no more than 5 kg, and a cast rim weighs 7-8 kg.

- On pressed products processed by milling machines, you will not find burrs or small flash along the edges, as is the case with casting.

- As a rule, inscriptions on alloy wheels protrude above the surface, and on forging they are deepened, because they are applied by extrusion.

- If the product is branded and is accompanied by documents, then in the forged rim specification you will find the corresponding English word - FORGED.

Advice. There are many exceptions to these rules that appear when studying the products of domestic or Chinese manufacturers. The best option is to buy forged rims v outlets with an impeccable reputation or from authorized dealers.

Despite the numerous advantages of light alloy wheels, they cannot win even half of the Russian market. A similar situation is observed in the countries of the former USSR, where stamped products are more relevant and more practical than aluminum ones. A change in trend should not be expected until there is a dramatic improvement in paved roads.

Instructions for using flushing fluid

Instructions for using flushing fluid Why do printheads burn out on Epson printers?

Why do printheads burn out on Epson printers? Installing and configuring the Canon i-SENSYS MF3010 printer Download driver for canon 3010 for scanning

Installing and configuring the Canon i-SENSYS MF3010 printer Download driver for canon 3010 for scanning