What are the advantages of alloy wheels over conventional ones. Light alloy wheels. Let's try to justify alloy wheels

Any car owner is faced with the need to purchase - it may be associated with their breakdown, the desire to change appearance vehicle or with a need quick replacement sets of rubber. The question inevitably arises as to which rims are better - there are many types of products on the automotive component market today. It is worth remembering that strength, reliability and other properties rims depend both on the material used in their manufacture and on the chosen production method.

The question that arises before many motorists: "Which wheels to choose?"

Iron

Budget cars or vehicles in the simplest configurations are usually equipped with stamped steel wheels. Such products are made from conventional rolled metal sheets of a given thickness - the blanks for the rim and hub are hot-pressed and then welded together. The use of steel makes it possible to achieve high strength of the discs, as well as their ductility. It is she who determines the main advantage of such wheels - when hitting a large obstacle or with a strong impact, they bend, but do not burst or crack. Therefore, the stamped disc can be repaired without the use of special equipment - just hit it with a sledgehammer or a heavy hammer.

However, to say which is better - stamped steel wheels or their expensive alternatives will definitely not work. The maintainability and low cost of such automotive components is opposed by a very large weight. An increase in the unsprung masses of a vehicle leads to an increase in the rate of suspension wear, a deterioration in comfort, as well. Most manufacturers try to lighten the forged discs by cutting special holes in them, but even such products weigh 2-3 times more than their light-alloy counterparts.

In addition, steel products are susceptible to corrosion, which can destroy them after 2-3 years of intensive use. They are coated with a primer or a special varnish to resist rust, but this solution is not able to provide ideal protection for the wheels. Finally, it should be noted the primitive design, which is rarely combined with the appearance of a modern car.

Classic casting

Most motorists are faced with a choice of alloy or stamped wheels. If financial resources are available, experts recommend choosing the second option. Light-alloy products are formed by the method of classical casting into a pre-prepared mold. Thanks to this, the border between the rim and the disc is virtually absent - this increases the reliability and durability of the wheel. As a material for manufacturing alloy wheels usually an alloy of aluminum with other metals, such as magnesium or titanium, is used.

By strength alloy wheels significantly outperform steel stamped ones. The limit of their deformation is much higher - in order to damage a wheel on an alloy base, 3-5 times more impact energy is required. However, the ductility of the alloy of non-ferrous metals is much lower than that of steel, which causes serious difficulties when it is necessary to repair the disc. To repair damage, hot rolling, drawing, argon welding and other methods that require the use of expensive equipment are used. After the discs are restored, the metal loses its original molecular structure, which leads to a significant decrease in the strength of the wheels.

If you want to know how alloy wheels differ from steel, you should know that light alloy products are much lighter. This has a positive effect on the following properties of the car:

- Comfortableness;

- Profitability;

- Reliability and durability of the suspension.

Alloy wheels are not subject to corrosion and other types of damage, even when severely damaged. The only exceptions are products with the use of magnesium - they are destroyed by moisture, which requires the use of multilayer protection. That is why on alloy wheels This type of balancing weights are recommended to be installed using a special polymer adhesive rather than traditional braces. An advantage can also be called the geometric accuracy of manufacturing - the tolerances do not exceed 0.1–0.15 mm, which ensures excellent control accuracy of the vehicle.

Maximum strength

However, light-alloy wheels are also available in various forms - if you purchase them in a large store, then after determining the required size, you will be asked if you need forged or alloy wheels? It should be said right away that mechanical forging has nothing to do with manual forging, which can be seen in small enterprises working with metal. In fact, forged wheels are made by stamping a light-alloy blank - the difference from the production of steel wheels is in the use of other shapes and the use of a very high temperature at which the metal is in a semi-liquid state. Forged wheels are also made of non-ferrous metals, but the proportion of high-strength components, such as magnesium or titanium, is much higher.

If casting involves the complete melting of the metal, accompanied by a violation of its molecular structure, then this does not happen during forging. As a result, the wheels receive even greater strength, which determines their reliability and durability. Experts say that hitting a large obstacle is more likely to damage suspension components than a forged wheel. The difference also lies in the mass, which is 5–25% less for products obtained by forging. This reduces fuel consumption, reduces wear rates and improves vehicle comfort.

The only major drawback forged wheels can be called a high cost due to the peculiarities of the production process. It is also worth mentioning that they cannot have a complex design, since the stamping mold imposes its own restrictions on the curvature of the surfaces. This is the answer to the question of how to distinguish forged wheels from cast ones - they have a coarse chopped shape. Despite some design restrictions, forged wheels are a favorite with street racers and tuning fans alike. They are able to improve the dynamic parameters of the car, as well as give it an unusual appearance.

What to choose?

If you are going to drive on good roads, but do not plan to spend a lot of money on equipping the car with new wheels, it is better to give preference to alloy wheels - recently many high-quality inexpensive models have appeared on sale. The best option is discs of Russian, Korean or European production, but it is better to avoid products from Turkey and China. For fans of high-speed driving, we recommend forged wheels, which are distinguished by their low weight and excellent durability. If you often have to drive on bad roads or even leave the asphalt, it is better to purchase stamped steel wheels... Their advantage lies not only in their low price, but also in the possibility self repair after a minor breakdown.

Today we will analyze the two giants of the market, again "casting" but only in comparison with the so-called "forged" disc. Which one is better, lighter, more reliable. There will definitely be a video version and a vote at the bottom. The information is chewed up in great detail, so read it - I promise it will be interesting ...

In general, I read a lot on the Internet, there are a lot of myths and secrets about each type of disc. Moreover, one can hear from many authoritative sources that alloy and forged wheels are made from ABSOLUTELY different materials, that they have nothing in common. That the difference is simply huge and forged it is some kind of space technology. BUT GUYS, in fact this is such nonsense! And today I will try to prove it to you.

Material from which they are made

As for forged and cast wheels, these are products similar in material, there are no space technologies here. What I want to say is that both discs are made from an alloy of aluminum, magnesium and a small addition of copper (very small, only 3 to 7%). So in terms of the structure of the metal, they are absolutely the same, of course, each manufacturer has its own formula, but it is never disclosed - it is kept “under seven locks”, because in fact it is a commercial secret.

The initial stage - that is, the melting of aluminum, magnesium (and copper, of course), it is always the same, these are large vats in which this soup is cooked. All the difference appears later, precisely during the manufacturing process. And here the differences are truly global.

Cast drive

As for the alloy wheel, I will not repeat its pros and cons (all this was in the article - about the comparison ""). However, I would like to remind you how it is made.

At the initial stage, as I said, the molten metals (aluminum + magnesium + copper) are freed from slags and poured into large bowls.

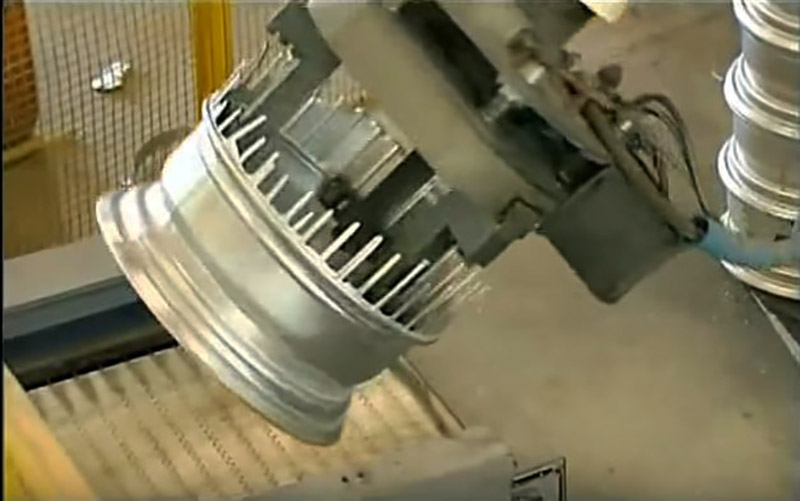

Further, from these "bowls" - they are poured into special forms - which, in fact, are already our disc. After the "rough detail", they pull out and grind on special machines - give high-speed and aesthetic characteristics (sometimes paint).

Actually, as you understand - this is a simple casting of metal into molds and then the usual turning, hence the name alloy wheels. Of course, this is very exaggerated, technologies have now stepped forward, but the essence remains the same.

The negative element of this production is end product strength ! But why?

YES everything is simple - "casting" is due to the fact that microbubbles, that is, empty cavities, remain in the material. Of course, these are not "giant" bubbles, do not think! They are really micro - a few microns, but there can be quite a lot of them (do not try to see them, it will still fail). They are formed during metal casting. In the final product, this carries degraded power characteristics. That is, this metal is banal, it can collapse due to these cavities, at maximum loads, because it is not homogeneous.

What the manufacturers do is that they simply increase the walls, make them stronger and thicker. Thus - the "cast" disc can withstand enough heavy loads, and moreover, it is lighter than "stamped", by 20, and sometimes 30%! Although in fairness it is worth noting - now there is a massive "casting" with designer patterns - it weighs about the same as stamping, but this is most likely an exception to the rule.

Forged disc

This is a completely different story. As I said, the initial stage, namely the melting of metals, is the same, but then it is a completely different technology.

Aluminum is poured into special shapes, initially they look like long, hollow pillars (like a very long cylinder). After the "pillar" has cooled down, they begin to saw it into short parts, that is, from one you will get several small cylinders (if you want it looks like cutting a log into logs).

After this "piece" is heated in the oven (not red-hot) and sent under a huge press - squeeze, several times, at a special angle - it is "flattened"! This process is remotely (very remotely) similar to "forging", that is, "metal on an anvil", hence the name forged.

After such a monstrous squeezing, the metal turns out to be fine-grained and fibrous; physically there can be no voids in it, which, upon impact, could lead to cracks or ruptures. But that's not all!

The first stage is the so-called "settling", the "block" is turned into a cake and again sent to the oven, heated. Then the stamp is changed on the press and the so-called "pans" are squeezed out of these cakes, which already vaguely resemble a disk, but without slots and holes.

And only the third time, the shape of the disc is squeezed out of the "pans", all the same on the same press. Here you can already see the "sides" and grooves that any disc has. But again, there are no slots and holes.

After three stages of forging, these blanks are "hardened", heated to 500 degrees and then sharply cooled in water. Thus, the structure of the metal becomes even more fine-grained, and even more durable. There are three such “hardening” stages, after which the disc is also artificially “aged”. That, according to the technology, also enhances it, because internal mechanical stresses are removed.

Then the forging is sent for machining. That is, in the workshop - where physically drills and other cutters will give them the desired look. They are lightened as much as possible, but they also leave stiffeners. After all, if the disc is lightened by 1 kilogram, then up to 60 kilograms more can be loaded into the car.

And then I want to debunk another MYTH - FORGED WHEELS ARE LIMITED IN PICTURE ! Nothing of the kind - just a limited number of companies make them, so the market saturation is NOT SO GREAT! THAT'S ALL! And so you can be knocked out (cut out) any, even more complex drawing than on "casting".

After machining, this is a finished version that will go on sale. BUT at the price they are the most expensive, because the technological process is very complicated.

Pros of forged options :

- Exceptional quality, because there are really a lot of verification stages

- High strength, such discs are superior to all existing counterparts

- Excellent speed characteristics, often do not require balancing

- Weight, 20 - 30% lighter than casting, and up to 60 - 70% lighter than stampings

- Less gas mileage

- Beautiful on the outside, aesthetically pleasing

- They do not rot, and do not rust, for they are made of aluminum and magnesium

Cons of forging :

- Expensive, sometimes twice as expensive as casting

- Hard, if you fly into a hole, it is mainly the tire and suspension that suffers, but not the disc, it practically does not deform

These are all disadvantages, of course there are not many of them, but again the PRICE is the FATEST disadvantage. Therefore, now many people vote with RUBLES for casting, and not for forged options - although the latter are more technologically advanced, lighter, just as beautiful, and so on (I gave you the layout).

Now the video version, we are watching

At this end, I think you liked my article, sincerely your AUTOBLOGGER.

The problem of choosing between steel and light-alloy wheels continues to cause a lot of controversy among motorists. Manufacturers add fuel to the fire by advertising their own products in every possible way for the purpose of selling. Therefore, stereotypes that do not correspond to reality have formed about the characteristics of products made from different metals. Hence the goal of this material- to tell the difference between stamped, forged and alloy wheels, how to distinguish them from each other and which ones are better suited for different operating conditions of the car.

Light alloy wheels

The name "light alloy" is given to these products because of the properties of the materials from which they are made. It is an alloy of light metals - aluminum and magnesium; titanium and copper are added to it in small amounts for strength and ductility. Hence the second name of such discs - titanium. There are 2 types of alloy rims:

- cast;

- forged (pressed).

These 2 groups of products differ from each other in manufacturing technology, operational properties and cost. To understand which one is better, you need to take a closer look at the production of discs.

This is how alloy wheels look like

Note. Sales representatives often impose on motorists the opinion that, unlike cast products, forged rims are made of incredibly strong and expensive metals, almost platinum. In fact, this is a myth, the composition of the alloy for the manufacture of both groups of products is exactly the same. Manufacturers can slightly change the ratio of base and additional metals in the melt at their discretion.

About production technology

As the name suggests, cast products are made by pouring molten metal into special molds (casting). The sequence of technological operations looks like this:

- Metals - Ingredients are placed in a furnace, melted and mixed.

- The alloy is fed to the mold and poured into it with a special ladle.

- After solidification, the workpiece is removed from the mold and transferred to machining. In this case, the structure of the rim and spokes has already been formed, all that remains is to remove excess material at the edges and refine the holes for the bolts, as well as balance the disc.

- The last stage is testing at certain speed and shock loads.

The robot moves the newly cast disc for machining

Reference. At factories of well-known brands, the process is fully automatic mode with the use of CNC machines, even the casting is performed by a robot. Manual labor is practically excluded.

Signature forged wheels with an openwork pattern of spokes

The name “forged” does not quite accurately reflect the manufacturing method of these discs, since they are not forged, but squeezed out of a heated alloy on high-power hydraulic presses. The manufacturing algorithm is as follows:

- As in the previous case, an alloy is prepared in the furnace, from which cylindrical billets are cast.

- Each blank undergoes several pressing operations, where a solid wheel rim without spokes and holes is formed from it.

- Products undergo 2 heat treatment operations - quenching (hardening the alloy) and tempering to relieve internal stresses in the metal.

- With the help of mechanical processing on a variety of machines, holes are made in the discs, the spokes are cut out, excess material is removed at the edges and balancing is carried out.

- Testing under critical loads is performed on special equipment.

Note. The second myth has been dispelled - that, due to the manufacturing technology, forged wheels cannot boast of a variety of designs. On CNC milling machines, you can cut any, even the most complex, pattern in the body of the workpiece.

Pros and cons of cast products

The main advantage of alloy wheels is their attractive appearance, which makes a car of any age and brand look much prettier. And the choice of products in terms of configuration and number of spokes is incredibly wide. This is the main reason that drives motorists to swap steel rims for light-alloy ones.

The rest of the advantages are also important, but they are of a technical nature:

- reduced weight of products gives less fuel consumption and increases the car's controllability;

- for the same reason, the acceleration dynamics of the car improves, and the braking distance is shortened;

- products are initially balanced due to production technology;

- long service life.

Of the listed positive points, only the durability and balance of alloy wheels is really noticeable when the owner of a car changes tires in a tire workshop. Improvement in handling and acceleration dynamics can only be felt by an experienced driver, and the change in fuel consumption is so insignificant that it is imperceptible at all (0.1-0.2 liters per 100 km of run). Therefore, beauty remains a priority. alloy wheels, and only then their technical parameters are appreciated.

It is difficult to deny yourself the purchase of such beautiful wheels when there is an opportunity.

Now about the disadvantages:

- Products are afraid of strong and sharp blows. A crack appears in the thinnest place or where an air cavity has formed inside the metal. The manufacturers claim that the castings cannot be repaired.

- The price of the product is higher than that of stamped steel discs. Due to the run-up in prices, the difference can be from 50 to 200%.

- Cast rims should not be used on vans and small trucks, as they are not designed for such loads.

- Operations for servicing such products at a tire fitting (changing tires, balancing) are more expensive.

Soldering impact cracks

Reference. In the countries of the post-Soviet space, there are many workshops where experts got used to soldering cracks aluminum casting... But such a repair cannot be called complete, and remanufactured discs cannot be placed on the front axle of the car.

Advantages and Disadvantages of Forged Wheels

The essential and only drawback of forged rims is their high cost, which is 2-5 times higher than casting, depending on the manufacturer. But for this money you will receive such advantages:

- reliability and durability;

- durability, a pressed rim will last as long as the car itself;

- low weight of the product (even compared to casting), which improves the behavior of the car on the road and reduces fuel consumption.

Thanks to pressing and hardening during the manufacture of such rims, the metal does not have hidden cavities and gains increased strength, therefore, impact cracks are an extremely rare case. In addition, the spokes of the product can be made thinner and more delicate, giving the wheel design additional lightness and beauty. This is what you pay your money for when you buy a forged wheel rim.

How to make alloy wheels - video

Steel stamped rims - the secret of popularity

More than 60% of all cars on the territory of the post-Soviet countries are equipped with discs made of carbon steel sheet. The vast majority of these cars are equipped with such wheels from the factory, since they are cheaper than others. Exceptions are luxury cars or elite brands, for which “stamping” is frankly not suitable in appearance.

The bent die can be rolled and aligned successfully

The most valuable advantage when driving on our roads is the high maintainability of the stamped discs and the ability to absorb impacts. In combination with the low cost, these features make traditional iron rims the most attractive in the eyes of ordinary users. To understand how their cost is formed, it does not hurt to get acquainted with the manufacturing technology of such products.

Manufacturing by stamping

Thick sheet steel is used to make iron rims. Two types of blanks are cut from it - a circle and a strip, sent for further processing. The process looks like this:

- On a hydraulic press, the core of the future disc with bolt holes and technological openings is stamped from a steel circle.

- The strip is sent to the rollers where it is bent into a cylindrical shape. The ends of the sheet are welded together, after which the seam is cleaned.

- A hydraulic press squeezes out the finished rim from the cylinder, then a hole is drilled into it for the valve.

- Both elements are connected by welding, then covered with primer and painted.

After hitting the press, the steel circle turns into the middle part of the rim

In the manufacture of stamped products, expensive CNC machines and furnaces are not used, which is why the energy costs are significantly lower. Hence the small price of the final product.

The rim is welded to the middle part

Video of the assembly process of stamped parts

Weaknesses of steel discs

Compared to pretty lightweight aluminum alloy products, forged iron rims are inferior in appearance, which often becomes the reason for their replacement. Plastic decorative caps, which are always lost on the potholes of our roads, do not solve the problem, and the owner of the car has to buy new ones.

For reference. To prevent the caps from flying off the wheels, many drivers fasten them to the disks with plastic electrical clamps. This helps, although it somewhat spoils the appearance of the car.

Genuine Volkswagen hubcaps cost fabulous money, but are lost less often due to good fastening

There are other negative aspects in the operation of “stampings”:

- due to the large weight of the wheels, the controllability of the machine is worse, and the fuel consumption is higher;

- increased braking distance;

- stamped iron products cannot boast of good balancing;

- metal rusts, and therefore requires maintenance.

Judging by the statistics, the listed shortcomings do not bother the majority of Russian drivers. Again, some of the negative aspects are misinterpreted by sellers. For example, the assertion that steel can rot in 2 years and the disc will become unusable for further use is groundless. To bring the metal to such a state, it will take a period twice as long, and with timely care, the product will last no less than light-alloy.

Note. There is a myth that the paint of stamped rims is easily scratched and quickly deteriorates, and the surface of the light alloy cannot be damaged. The second part of the statement is incorrect, alloy wheels can also be scratched, but painting them is much more difficult.

The choice of the type of rims is best done according to three criteria:

- depending on the operating conditions of the machine;

- class and brand of car;

- active driving in a cold or warm season.

Advice. If you expect to use one set of rims all year round, then, taking into account the Russian road conditions, it is better not to risk money and put steel "stamping".

The ideal option is to have 2 sets of discs, using them in the warm and cold seasons. For summer driving on asphalt surfaces, light-alloy rims are perfect, but for the winter you need to put stamped ones. The problem is the ice that appears on the asphalt due to uncleared snow, which makes the flat road covered with solid potholes. The same ice on the edges of the roadway will easily scratch your beautiful titanium wheels when driving to the curb or coming close to the curb.

When choosing a set of new disks, it does not hurt to take into account other recommendations:

- Don't shell out and buy light alloy products if you are driving an SUV through the fields. And vice versa, it is not necessary to put “stamping” on elite cars operated on flat roads, it looks reprehensible.

- Forged wheels are suitable for any passenger car and various driving conditions, except for open off-road.

- Do not try to fit light alloy rims on a commercial van, as you run the risk of quickly rendering them unusable.

When choosing forged products, a natural question arises - how to distinguish them from casting with external similarity. After all, an unscrupulous seller can slip you a cheaper product at the price of forged wheels. There are a number of tips on this subject:

- Forging is easier than casting. For example, a 15 "forged rim weighs no more than 5 kg, and a cast rim weighs 7-8 kg.

- On molded molded products, you will not find burrs or small burrs around the edges, as is the case with casting.

- As a rule, the inscriptions on cast discs protrude above the surface, and on forging they are recessed, because they are applied by extrusion.

- If the product is branded and accompanied by documents, then in the specification of the forged rim you will find the corresponding English word - FORGED.

Advice. There are many exceptions to these rules that appear when studying products of domestic or Chinese manufacturers. The best option is to buy forged rims v retail outlets with an impeccable reputation or from authorized dealers.

Despite the numerous advantages of light-alloy wheels, they cannot recapture even half of the Russian market. A similar situation is observed in the countries of the former USSR, where stamped products are more relevant and practical than aluminum ones. Changes in the trend should not be expected before there is a dramatic improvement in paved roads.

And how to do it correctly - every motorist needs to know all these points. We will help you understand the intricacies and become a real professional in matters related to car rims.

Modern disc range

Steel wheels that have been installed on all cars around the world have a centuries-old history. With the advent of cast models from previous copies, no one was in a hurry to refuse. Alloy wheels have their own advantages, which are expressed in attractiveness and higher reliability. But the high cost spoils everything. The latter have developed forged models that are in many ways superior to their counterparts. But again, the high cost becomes a stumbling block. product makes users think about what is best for their car, what is the difference and which choice will be most appropriate.

Humanity has not yet managed to create ideal car wheels that could satisfy all the needs of car owners and surpass existing analogues in each of its parameters. Each user has to choose the most appropriate option, analyzing the pros and taking into account the cons.

The stamped steel product is the most affordable option from all the possible suggestions. Aluminum products will cost at least twice as much. Stamped products run the risk of bending when the car passes through the pits. This is their advantage, because the main impact will be on the disc, and not on the body and suspension.

The stamped parts weigh a lot, which creates an obstacle to quick acceleration and good braking. The installation of such an element on the car instantly increases the unsprung mass of the vehicle, which negatively affects the level of passenger comfort and the operation of the suspension. If you think about which disks are better to choose, then this option is most suitable. After all, in winter, no one is chasing dynamics.

There is no need to use high pressure in the production process. The final product is light, but not particularly pliable. Such discs do not bend, but they often crack from impact. The wide variety of design options and the increased number of vents for air ventilation and quick brake cooling are the advantages that set the cast product apart from the stamped product.

In terms of value for money, it is the cast models that take the lead among all available wheels.

There are many similarities between cast and forged wheels. The alloys are the same, but they are processed differently, which makes the forged product extremely strong and even lighter than its cast counterpart. Bend well and rarely crack, but are very expensive. The creation process is complex and lengthy, it consists of two stages (hot stamping and chemical or thermal processing), so manufacturers cannot offer a wide range of design options.

The forged product is not affected by weather conditions, moisture and frost. They do not form on them, therefore, treatment with appropriate protective compounds is not required. For a forged disc to deform, a great deal of force must be applied. He can only bend.

The difference in price is very significant, but you always have to pay for quality.

Distinguishing between forged and alloy wheels

Even though we live in modern world where civilized market relations prevail, but situations are different, so the buyer should be well oriented in the purchased product. And it will not be superfluous to know how alloy and forged wheels differ.

Weight refers to the main parameter that can be guided by. A forged model with a 15-inch diameter will weigh up to 5 kg. But if you take a similar cast wheel, then its weight will increase by 3 kg. Domestic automotive products lend themselves to such a comparison, but if a European cast wheel enters the ring, then its weight will be equal to a forged product from a Russian manufacturer.

Labeling is another parameter that can help you distinguish between two different discs. Forged wheels undergo a stamping process during serial production. Therefore, the markings are depressed. On cast wheels, marking is carried out in a different way, as a result of which the inscription is convex. There are exceptions to this question, but they are rare.

The shape of a rim can also tell you what type it is. Cast models rarely lend themselves to milling, which affects the presence of slightly uneven edges. But forged models go through the turning stage without fail, so the edges are always smooth. Previously, this difference was clearly visible. Now, new equipment and improved technologies make it possible to immediately obtain a smooth cast product, which becomes more difficult to distinguish from a forged counterpart.

The specification appears in a certificate that the disc seller must provide. If the product is forged and released in legal production, then it will be designated as forged. A product manufactured in Chinese and Turkish factories is not always labeled in this way.

Cast and forged wheels we figured it out, but there is one more category that remained unexplored. Cast or stamped - what to choose and how to distinguish them from each other. The appearance immediately gives these two varieties of one product. The cast version looks more presentable and solid, the range of design options is rich and varied. Stamping looks unpresentable, however, for such low price hope for something more is not worth it. You can also focus on weight, the differences are not particularly significant, but still.

Here's another topic, we helped you figure it out. Now or to the market you can go with confidence in the right choice which will be easy to do.

The best prices and conditions for the purchase of new cars

Credit 4.5% / Installment / Trade-in / 95% of approvals / Gifts in the salonMas Motors

Long ago in the past. Today, no one thinks about how to mothball their car before the onset of spring, and in winter, cars are operated in the same way as in the warm season. However, this does not mean at all that winter operation does not require absolutely any preparation for the coming cold weather, on the contrary, it costs a motorist no less to prepare for winter than for the same conservation. Preparing a car for winter operation provides for a whole range of measures, including:

- Checking the level and condition;

- Stove check;

- Replacing the summer "omyvayka" with a winter one;

- And, of course, changing shoes in.

Last question we have already raised on the pages, but the question of what is better to buy for the winter - alloy wheels or stamped ones, remained unresolved for many. Therefore, today, by popular demand, we decided to figure out what is better - casting or stamping?

First, a few words about what steel and alloy wheels are.

Steel, or as they are also called stamped discs, are made by stamping. That is, they are cut from a solid sheet of solid sheet steel. After that, the individual parts are welded and painted. The stamped discs are distinguished by a budget price, high strength, and resistance to various deformations. Unlike cast analogs, the dents of metal discs are easy to straighten (roll back). Also, the advantages of stamping include resistance to low temperatures.

The disadvantage of stamped discs is their unpresentable appearance and high weight in comparison with alloy discs.

Alloy wheels or "titanes" are made by melting light alloys (aluminum) and casting into molds. This makes them lightweight, durable and very attractive. Some discs are machined from a solid billet of aluminum. The disadvantage of alloy wheels is their instability to shock and damage. After a strong impact, especially at high speed, the disc may deform, crack, or receive numerous chips that cannot be repaired. In addition, despite the numerous denials of fans of casting, alloy wheels are still "afraid" of low temperatures. No, they do not crack from frost like a wet stump, but at subzero temperatures, their strength is significantly reduced and what would cost you a little restoration work in the summer can turn into a complete destruction of the wheel rim in winter.

In general, these two types of discs have been competing with each other for a long time and this is not only a "seasonal aggravation", there are both fans and ardent opponents of both types of discs. Therefore, in order not to take sides, we will try to remain neutral and look at the controversial issue from the point of view of independent experts. In this article, we will look at the clear advantages of cast and stamped wheels, if any, point out the disadvantages, and, as always, leave the choice to you. Only in this case we will focus on winter operation. So let's go ...

As you know, the vast majority of inexpensive cars, despite the popularity of alloy wheels, are equipped with stamped analogs. Someone immediately changes the stamping to casting, someone absolutely does not care what to ride, and someone, like you and I, racks their brains over the question of what is better after all - buy cast or stamped wheels.

The main reasons why stamping is used for the winter

The first reason why stamping is used in winter is budget. Stamped discs due to their low cost, so to speak, "it's not a pity." Even if something happens to the iron "rollers", no one will be very upset. In addition, if you once "changed your shoes" on such disks into winter tires, with the onset of heat you can remove the disks with rubber and postpone until the next cold weather, which is very convenient and profitable considering the cost of tire fitting (2 times a year summer-winter, winter summer). With alloy wheels in this matter, everything is much more complicated. Firstly, the price of alloy wheels, provided that they are of high quality, is quite high and not everyone can afford it, and if you imagine the situation with the purchase of two sets of winter-summer, then it is quite an expensive pleasure. And changing shoes twice a year is also not the best option.

The second reason why it is beneficial or, more correctly, convenient to use stamped wheels in winter is the safety of alloy wheels. The harsh chemicals that are used to treat roads in winter have a negative effect not only on the car body, but also on the wheels. Therefore, it is more expedient and cheaper to "destroy" cheaper stamped discs than expensive cast analogs. In addition, if we consider that in winter there are many hidden pits and ice-covered obstacles on the roads that damage the paintwork of alloy wheels, then it can be concluded that stamped wheels for winter are just the right thing!

The third reason - more open alloy wheels are more forgotten by snow than stamped analogs. Then there is friction, problems with the brakes, etc.

Let's try to justify alloy wheels !?

The fragility of alloy wheels in frost, which we talked about above. In principle, this is true. Really aluminum alloys at subzero temperatures they become more brittle. But if you look at it from the other side, you can note the fact that critical temperatures are characteristic of certain regions in our country, for example, somewhere in Siberia, but even there the temperature does not often drop below -40 ° C. So this argument can be questioned or not taken into account at all.

In winter, due to slippery roads, there is a high probability of a side impact on an obstacle (curb, ice hole, pieces of ice, etc.). After impact, they are often damaged and require expensive repairs or cannot be restored at all. Yes, there is such a thing, but if you live in a city where the roads are at least a little cleaned and treated with reagents, then we can say that the probability of getting into a similar situation is quite small. In addition, in winter, adequate people who take care of themselves and their car do not drive fast, and even if you catch a hole in the road, then most likely the alloy wheel will remain intact after that.

Snow in cast wheels really does not play in favor of alloy wheels, because of their open design, wet snow and frost, which often replaces it, can play a cruel joke if you use cast rollers in winter. However, in most cases, casting manufacturers work on mistakes and modern alloy wheels have a design capable of self-cleaning from snow while the car is moving. In addition, alloy discs are easier to clean from ice and snow than metal ones, in addition, the cooling of the brake elements in cast analogs is much better due to the same open configuration.

Alloy wheels. This item is relevant only if the discs are Chinese or hand-painted. Qualitative branded alloy wheels have a fairly durable paint and varnish coating, as a rule, an order of magnitude higher than the coating of many steel analogs. And if you are not going to drive off-road with thick ice or virgin soil, then in principle you have nothing to fear.

As you can see, both discs have a number of advantages and disadvantages over each other, and some disadvantages, if you look at them from a different angle, may turn out to be just fiction or just a myth. The most important thing is to understand for yourself what will be better for you and your car in a given period of time.

Let's summarize

If you know that your winters are harsh and you will not be driving the most better roads, then, perhaps, a wiser decision would be put stamping on the winter, they are not so pity in case of damage, they are more hardy and shock-resistant than alloy wheels.

If you have high-quality alloy wheels covered with factory paint, you live in a region where temperatures are too low - a rarity, you move exclusively around the city, where the roads are mostly clean - you can safely use alloy wheels. Careful operation and respect will hardly harm your cast rollers in winter. The only thing worth thinking about is whether it is worth constantly going to the tire service when changing tires, or maybe it is worth buying an additional set of alloy wheels for the winter.

On this, our short opus has come to an end, thank you all for your attention, everyone who wants to add or express their opinion on this matter can do this using the comment form. Until then, and see you next time. Take care of yourself!

How to download videos from Yandex Disk to iPhone: an easy way

How to download videos from Yandex Disk to iPhone: an easy way License Agreement for the terms of use of the Dr software

License Agreement for the terms of use of the Dr software Airyware Tuner - the best tuner in your smartphone Application for tuning guitar on Windows background

Airyware Tuner - the best tuner in your smartphone Application for tuning guitar on Windows background