Alloy wheels Japan firm. Which discs are best

As soon as a person acquires his own "wheels", a lot of problems immediately appear, which are not familiar to the "horseless" citizen. One of those headaches is choosing rims.

Despite the fact that the showcases of car dealerships amaze the imagination with an assortment, according to the production method, rims are divided into only three types: stamped, cast and forged.

Its sleek, ten-cross-spoke race design pairs beautifully with the edgy "beginner" look. The cold season brings with it snow, ice, sand, salt and debris. However, it is difficult to predict when your vehicle will be dealing with these elements.

The famous slogan of the Austrian capital is still remembered by many people. Variants of flying wheel rims are not just rendered harmless by them. Alloy wheels much more pleasing to the eye than steel, but their capabilities and functionality are much more important. Characteristics, first, weight and strength. Cast rim is much lighter than steel by 20-50%. This means that the car will move more easily because it is lower and so on. The "unscrewed" mass is the weight of the wheels, brakes, and whatever hangs under the suspension.

Each type has its pros and cons. Let's find out with our car instructors .

Steel discs

Stamped discs have been used for as long as mass production of cars has existed, and until the 80s of the last century, motorists simply had no alternative.

The method of production of such disks is simple: two halves of the future disk are cut out of a straight piece of steel by a mold. Then the inner and outer parts are connected by spot welding. Then it remains to apply a protective anti-corrosion coating - and the disk is ready.

If it is lighter, the faster and better the vibrations and vibrations of the cabin, which in turn means a smoother ride and better dynamic qualities. Alloy wheels are not made of soft pure aluminium, but of its alloys. Their properties of aluminum wheels have the following advantages, better withstand the impact of steel and more successfully retain their shape. If we do not count the extraordinary holes and bumps that we can only find in Bulgaria, aluminum wheels are practically eternal, and for scratches they are easily removed by polishing.

If you press the rim and seriously damage it, it's best not to repair it. because the aluminum rim goes through heat treatment, and all subsequent impacts and repair of damaged rings through deformation create microcracks in their material, which can lead to the rim breaking during movement.

Advantages of stamping:

- Low cost and, accordingly, the price. A domestic-made disc costs an average of 500 to 1500 rubles.

- High plasticity, due to which, upon impact, the disc absorbs the impact energy, protecting the suspension and tire.

- Maintainability - a bent disk can be straightened for reuse.

- Wheels with such disks are not in great demand among car thieves.

Disadvantages of a stamped disc:

If you really want a stronger rim, then go for a fake one, which is also aluminum based but hot pressed. This type of rim is even stronger and lighter than standard cast aluminum. In stroke, forged wheels do not crack, but deform, which makes them possible.

When buying aluminum wheels, you need to look for the exact location of the diameter, width, number and diameter of the mounting holes. Create a face if possible. Be sure to bend each wheel with a tire on it after purchase. Last but not least, the bolts or their nuts for fastening are different from the bolts for steel wheels! Never use old ones made of steel, because they are smaller and easier to insert into aluminum, and therefore there is a necessary condition for a crash due to riveting from the rim!

- Big weight. The manufacturing technology does not allow to reduce the thickness of the metal without loss of strength characteristics. Therefore - huge pressure on the chassis, longer stopping distance, fuel consumption and a large number of related troubles.

- Unpresentable appearance. Again, the technology does not allow complex designs to be obtained. Discs have to be covered with caps.

- Low corrosion resistance. Especially on inexpensive models, where the coating is applied using a simplified technology.

Alloy wheels

Alloy wheels are made from aluminum alloys by casting. Logical, right? Casting is made by three methods - die casting, low pressure casting and counter pressure casting. The performance of the wheel depends on the manufacturing method.

And one more useful advice A: Tell your insurance company that you have wheels on your car. For this reason, they will not change the price of your insurance policy, but it is important to know and reflect it on the insurance policy. If you're new to roller coasters, it's hard for you to decide which roller coaster model to buy.

The following text is dedicated to you! We talk about rolls, explain the meaning of symbols, translate typologies and simplify definitions. The roll includes: shoes, sleds, wheels and bearings. There are two numbers on the roll. The first is expressed in millimeters, for example, 78 mm, and the second - with the letter A.

Thus, disks produced under low pressure are 1.5-2 times superior to die casting in terms of plasticity and 15-20% in strength. And casting under counter pressure improves mechanical properties by another 5-10%.

Also, cast wheels differ in the material of manufacture. The most common alloy is aluminum and silicon. Such wheels are 15-30% lighter than steel ones. Magnesium alloy wheels are the lightest, but at the same time the most fragile. In addition, magnesium has a low corrosion resistance, which makes it necessary to apply a strong protective coating on such discs.

The first number is the size of the wheel, and is actually the diameter of the wheel in millimeters. The second number is the hardness of the wheel. Both sensors have great importance for speed, fluidity and driving comfort. The larger the wheel, the higher the speed on the rollers. But the more wheels, the less twist and turn the rollers are. For example, the circles in aggressive rolls are tiny. Aggressive skates can't reach high speed but they are very torsional responsive and they are perfect for slalom, sharp turns, jumps, rails and other evolutions.

Fitness skates with 84 mm wheels are very fast - for recreational skates - models. Today, the wheels in most rolls are made from polyurethane, a synthetic rubber. The letter A is the Shore symbol used for polyurethane products. The higher the A number, the more complex the polyurethane from which the wheel is made. In recreational rolls, the average wheel hardness ranges between 78A and 82A.

Casting pros:

- Lower weight compared to forged wheel. Accordingly, the driving performance of the car is improved, the load on the suspension is less, and less wear on the rubber. In addition, the heat dissipation characteristics of such discs do not allow the brakes to overheat.

- Technology allows you to get many design options. If you need to make the car look, then casting is the best solution.

Cons of alloy wheels:

The more complex the wheel, the more durable it is, the less it rubs and the less often it needs to be replaced. But the more comfortable the wheel, the better grip and better grip. Wheels with lower hardness polyurethane absorb shock better while driving. They provide natural cushioning by absorbing vibrations. These wheels make it easier to ride on bumpy roads and uneven terrain. However, soft wheels wear out faster, are less durable, and are slightly slower. Also, when choosing a wheel, you need to weigh the weight of the roller.

People with high body weight should wear a wheel with hard wheels. The 80A hardness wheel seems to be the most compromise between driving comfort and wheel strength. There are three types of skid: aluminum, composite and plastic. Theoretically, aluminum sleds are the most stable, the most stable, and the most stable. Composite skids are qualitatively weaker - they can withstand up to three seasons of sharp and regular driving. However, freestyle skates are made on a compound skate because while it sheds faster, it absorbs well, plastic sleds lose quality visually faster because they draw and copy quickly.

- The main disadvantage of such wheels is their fragility. When hitting a disk, it can easily crack. What this means for the safety of the car, no need to explain.

- Poor resistance to corrosion and the formation of galvanic couples with steel parts. This is especially noticeable on discs made of magnesium alloys. Breaking the protective coating can be the beginning of the disk destruction process.

Of course, on discs made in compliance with all the rules, the risk of destruction is minimized, but the market is inundated with products. Low quality and of unknown origin. So there is always a chance to get wheels on your car that can fall apart on the first curb.

They are very good for aggressive driving and driving evolution because they are best for vibration and damping. The type of bearings affects the speed, smoothness and smoothness of the ride. The symbol always contains an odd number: 3, 5, or 7. Therefore, bearings with a large number are used for fast operation.

Larger balls are better able to withstand higher loads. This means they are ideal for heavier people and for driving that imposes heavy G-forces - such as hockey, aggressive driving or fast riding. They are specially designed for use in rolls.

Prices for alloy wheels depend on the manufacturer and vary from 1,500 to 30,000 rubles.

Forged wheels

Indeed, it is somewhat inappropriate to call wheels made using the technology of hot die forging in closed matrices “forged”. But, since just such a name has taken root among the people, we will leave it for ease of understanding.

And the greater the density, the less dirt, the longer. The roller shoes have special attachments that make the rolls comfortable - they provide comfort during hard riding and hold the foot firmly to ensure stability. There are several types of fasteners, each with two or three fasteners.

Each roll has a buckle and Velcro. Some models of rolls have additional lacing. We hope this article has shed light on the slightly complex world of rolls. Before you decide to take a look at the roller models and choose the model that suits you, take a look at the up-to-date text and information.

So, "forged" wheels are a purely Russian invention. They appeared in those years when the defense industry needed to survive. So the inventive comrades thought of making automobile wheels on equipment hitherto used in the aerospace industry.

Hence the high cost of such products - the disks are made in the course of a multi-stage technological process using presses that develop a force of 6 to 20 kilotons. Such presses cost tens of millions of dollars and are available at a few enterprises - both in Russia and abroad, and therefore the manufacturers of "forged" disks can be counted on the fingers.

When it comes to what kind of rims to put on our cars, there is no driver who doesn't want big and shiny alloy wheels. Looks great on the car. The main reason drivers fit their alloy rims is because the car looks different. There are hundreds or maybe thousands of models on the market, and you can choose from them, with manufacturers competing on more interesting designs. Provides better brake cooling.

The disadvantage of many is that alloy wheels provide better brake cooling. This is explained by the fact that aluminum is a better conductor than steel. Alloy wheels do not rust. Aluminum or magnesium does not take into account changes in humidity or temperature, nor does steel, and therefore does not rust.

The process allows you to achieve a uniform and fine structure aluminum alloy, forged wheels are so light and strong.

And dear ones. Although, it depends from what position to judge. If a Russian "forging" has to buy at a price of 4-7 thousand rubles, then abroad the same disk will cost over a thousand euros.

Advantages forged wheels:

Saves its resale. Aluminum wheels from major manufacturers retain their value over time and can be sanded without a problem. Compared to wheels, alloy wheels are expensive and sometimes don't justify our price. One solution is rim protection. Especially in the cheapest, low quality. The lake begins to have defects, scratches, after which the material oxidizes below, and the lake begins to grow.

Cracks, bumps and cracks in the alloy are much more common than wheel rims. The problem is that with a stronger impact, the alloy breaks instead of bending. Not only rebuilt and welded alloy wheels, because if we take a big pit with a car, the wheel will bend or break.

- Light weight. Two times lighter than steel, 30-40% lighter than cast ones.

- High impact ductility. It is almost impossible to split a high-quality wheel. And when dents appear, it can be corrected.

- Corrosion resistance.

Disadvantages of forging:

- Relatively high price. The cheapest "forged" is twice as expensive as the cheapest cast.

- Unassuming design. Theoretically, you can get a shape of any degree of delicacy, but "forged" discs are much thinner than cast ones, and therefore beauty will worsen the strength data.

By the way, this is one of those types of products that are exported. So, if someone covets foreign "forging", most likely, he will purchase a product made from our blanks.

If we take our own roads, all cars in Romania must only have rims on board. Steel doesn't scratch deeply like aluminum, which leaves deep grooves when we reach the parking beam. In addition, steel rims feel stronger when we press the steering wheel, at high speed, the drum.

Most new cars come from the factory with sheet metal rims, for the simple reason that they are cheaper. While we would presumably be tempted to believe that they are heavier than alloy wheels, the ones in metal are lighter than most alloy wheels. Being lighter, it also results in better fuel consumption.

And here is a video on the topic of choosing types of disks for your car:

What to put on your car, everyone decides for himself. Cheapness, appearance, safety and excellent driving performance of your car - everyone has something to choose for themselves.

If you want to change the wheels on your car, then you need to know a few important things to make the right choice. Consider labeling car rims. All discs have a standard marking of parameters, regardless of whether it is an alloy or steel disc.

Not because the material is softer, but because the sheet resists better straightening and doesn't crack like aluminum. The beautiful sheet does not have a rim, and for this reason, expensive cars are never equipped with such rims. For the same reason, rims are often covered with caps.

Sooner or later, rust will appear, further destroying their appearance. How alloy wheels, they can be repaired or refinished. Because the balance wire is fixed on the lip of the wheel, instead of being inserted inside, as in the alloy.

Both types of rims have their own advantages and disadvantages, and it's up to you to know what each one means. What wheels do you choose for your car? If you want to keep your vehicle safe while driving, you should also consider opting for alloy wheels. They can give you various advantages over steel. Therefore, the main advantages are: reduced weight of steel rims, their very pleasant appearance and steel resistance.

Marking rim

For example: 8.5Jx18 H2 5x120 ET20 d74.1

8.5

is the width of the rim in inches (W);

18

is the disc diameter in inches (D);

5x120- this is a designation for the number of landing bolts and the diameter on which they are located. This diameter is also referred to as PCD, and it is measured in millimeters. In our case, the number of seat bolts early is 5 and the PCD is 120 mm;

ET20- disc ejection. This is the distance between the mating plane of the rim (the plane by which the rim is pressed against the hub) and the axis of symmetry of the rim (CL). Departure (ET) is measured in millimeters. In our case, it is 20 mm;

d74.1- the diameter of the central hole, which is measured from the mating plane. Diameter (DIA) is measured in millimeters. In our case, it is 74.1 mm. Many manufacturers alloy wheels they make DIA of a larger diameter, and for centering on the hub they use adapter (centering) rings that securely fix the disk, eliminating the possibility of vibrations.

Of course, all these features are highly dependent on the model chosen, but also on the company that makes them. Many people think that these types of wheels cannot be repaired, but this is not always the case. There are, of course, cases where such a rim cannot be repaired, but many times a reliable specialist can repair an alloy wheel without any problems.

There are thousands of different models of such rims on the Romanian market, so you can choose according to your needs or preferences. In this short guide, we will show you the most important characteristics of your alloy wheels so that you can make right choice in terms of the amount of money you are willing to pay, as well as other aspects.

The marking also contains additional parameters J and H2, but they are of interest only to specialists.

J - this indicates information about the design of the side flanges of the disc rim. There are: J, JJ, K, JK, B, P and D.

H2 is the designation of the hump design. Humps are annular protrusions on the landing shelves of the rim. There are: H, H2, FH, FH2, CH, EH2, EH2 +.

Let's take a closer look at each of the disc labeling options.

I think that the width and diameter of the disk do not require additional interpretation.

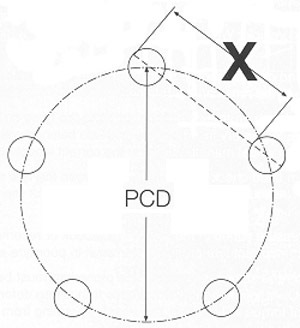

As mentioned above, PCD is the diameter of the circle on which the mounting holes are located (in the picture below it is indicated by a red line).

If necessary, PCD can be calculated by measuring the distance between the centers of the nearest holes (this can be done with a regular ruler without removing the wheels from the car). For discs with four mounting bolts, PCD is equal to the distance between the centers of opposite bolts.

The following formulas are used to calculate PCD:

3 holes: PCD=X*1.154

4 holes: PCD=X*1.414

5 holes: PCD=X*1.701

6 holes: PCD=X*2

10 holes: PCD=X*3.326

ATTENTION!

Since the mounting holes are made with a solid plus tolerance in diameter, you can make a mistake in choosing a PCD if it differs from the standard one by a couple of millimeters.

For example, a PCD 98x4 wheel is often put on a hub with a PCD 100x4 (you can’t distinguish 98 mm from 100 by eye). IT IS UNACCEPTABLE. In this case, of all nuts (or bolts), only one will be fully tightened; the rest of the holes will be "taken away" and the fasteners will remain undertightened or tightened with a warp - the landing of the wheel on the hub will be incomplete. On the move, such a wheel will “beat”, in addition, not fully tightened nuts will unscrew by themselves.

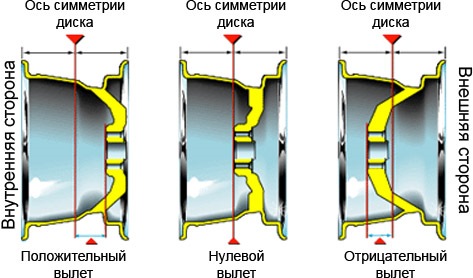

As we said above, offset (ET) is the distance between the mating plane of the wheel disk (the plane that presses the disk against the hub) and the axis of symmetry of the disk. Wheel offset for any car model is calculated directly by the car manufacturer. Accordingly, compliance with this parameter when choosing a disc is a very important condition for its safe location in the wheel arch. It is allowed to change the overhang by no more than 5-7 mm.

Departure is positive, zero and negative.

What is the flight

Zero overhang means that the mating plane of the rim completely coincides with its axis of symmetry.

Positive overhang: the mating plane is offset from the axis of symmetry in the outer direction (roughly speaking, towards the road, and not towards the body).

With a negative value of the offset of the rim, its mating plane, on the contrary, is shifted towards the body. Typically, negative offset is found on discs with a deep-dish design.

Russian tire manufacturers also use the following wheel offset classification:

short overhang: 0 to 30;

normal departure: from 30 to 45;

long reach: from 45 to 100;

negative offset: -25 to 0.

ATTENTION!

Departure parameters are strictly regulated by the automaker and are strictly related to the kinematics of the suspension. When it changes, the loads change dramatically. For example, it is believed that with a decrease in overhang by 50 mm, the load on the suspension increases by 1.5 times. Simply put, the wheel begins to act as a lever, which is especially pronounced in turns, when dynamic loads increase. This is due to the fact that the ratio “turn line - wheel center” set by the manufacturer is violated, resulting in a negative or positive rolling shoulder. Its influence lies in the fact that there is an additional moment that must be compensated by the steering wheel. The result is heavy steering and unpredictability in corners. And of course the suspension wear.

Instructions for using flushing fluid

Instructions for using flushing fluid Why do printheads burn out on Epson printers?

Why do printheads burn out on Epson printers? Installing and configuring the Canon i-SENSYS MF3010 printer Download driver for canon 3010 for scanning

Installing and configuring the Canon i-SENSYS MF3010 printer Download driver for canon 3010 for scanning