Russian manufacturers of rims. The most beautiful car rims

Correctly and competently selected wheels for a car are not only your safety and care for passengers, but also low fuel consumption along with an increased transmission life and a fascinating view of a stylish car.

Let's try to figure out how to choose the right one alloy wheels and use them competently. The opinions of intelligent experts in this field and the recommendations of popular manufacturers of light-alloy products will be taken into account.

Types of discs

All wheels can be divided into two groups - steel and light-alloy (cast). The design of the stamped wheels is simple and straightforward. stamped and the individual parts are connected to each other by spot welding. The disc is then dyed and sent to a store or conveyor.

This method of equipping the car with disks is simple and inexpensive. A significant mass of cars coming off the assembly line have just such wheels. Casting installation is already an additional option, for which you need to pay a decent amount.

Before choosing alloy wheels instead of steel, in favor of the latter, we can say that they have more, which means that after strong blows they do not crumble or crack, but only deform. This feature allows you to recover the disc, even if the edges are heavily crumpled.

A significant drawback of stamped products, which is critical for many motorists, is weight. Moreover, it cannot be reduced, because insufficient wall thickness significantly reduces the strength indicators of the entire wheel. In addition, steel models are susceptible to corrosion if the integrity of the protective coating is compromised. This also includes a monotonous and boring appearance, difficulties with and a negative impact on the dynamics of acceleration.

Alloy wheels

Before choosing alloy wheels, it is useful to know some of the advantages. Light-alloy models offer ample design possibilities along with high precision workmanship. They are able to remove most of the heat from the main components, but the most important thing is the lightness of the structure. It is possible to judge the specific merits of certain models if it is known how they were cast and with which alloy. So in this case, the wheel is the wheel of strife.

Ordinary models are made by casting or forging from resistant alloys, where the basis is aluminum, titanium or magnesium. Magnesium and titanium models are much stronger and lighter than aluminum rims. Before choosing magnesium-based alloy wheels, know that they are less resistant to corrosion, which means that you will have to constantly take care of a multi-layer protective coating. As for titanium, this is already an elite group, which is equipped with very expensive, sports and simply prestigious cars. For everyday driving on our roads, titanium models are simply a pity to use. Despite the strength of such products, they are prone to scratches.

Difficulties of choice

Before choosing alloy wheels for a car, remember that the purchase should be determined by your needs and, of course, by the amount in your wallet. If your path is megalopolises and large cities, then magnesium or aluminum casting... Are there free finances? Please, titanium models are beautiful, super reliable and will be a great addition to an elite environment.

If you value reliability, often drive outside the city on bad roads and do not attend social events in your car, then it is better to stop at steel, stamped or forged products. In this case, they will not only be more practical, but also save you the lion's share of the family budget.

How to choose the right alloy wheels for a car

In order to correctly select this or that disk model specifically for your car, you need to clearly clarify some critical parameters. First of all, we find out the width and diameter of the disc. Then we clarify the location of the mounting holes and their number. Next, we pay attention to the diameter of the hub of your car and the departure indicator. All basic installation dimensions can be viewed in the catalogs of tire and wheel manufacturers or you can measure everything yourself using a special tool. Before choosing alloy wheels for a car, and if suddenly there are any doubts, it is better to go to a sensible tire fitting and figure everything out there, drawing on a piece of paper all the sizes and parameters of interest to us.

Disc diameter

This parameter is selected according to the recommendations of your car manufacturer. It must exactly match the wheel rim. Recently, there are more and more extremals who seek to increase the mounting diameter. For example, a 15-inch fit is rolled under 16, 17, or even 18-inch wheels.

All this is done for the installation, which, on the one hand, increases the driving performance for the better, and on the other hand, increases the load on the main suspension units. And the comfort of driving on such rubber is not the best. Before choosing alloy wheels of this or that diameter, you yourself have to decide for yourself what is more important - sports performance or driving comfort?

Rim width

If the manufacturer's recommendations for the mounting diameter for your rims do not exceed the 14 "mark, then the rim width will fluctuate between 0.5-1.0". For mounting diameters over 15 ", the width will be slightly higher - 1.1-1.5" for the rim.

Which alloy wheel to choose is up to you, but the best and more practical option would be a factory-width product. The use of non-standard wheels for your car is fraught with changes in the design profile of the tire, as a result of which the basic driving characteristics (pullback resistance, reaction to the steering wheel and lateral stiffness) can be significantly impaired.

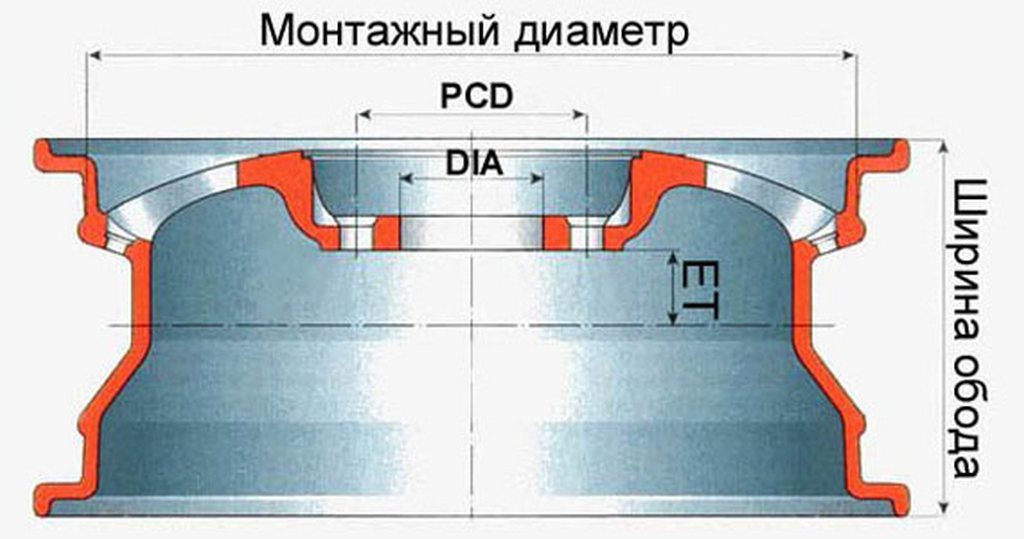

Wheel departure

Reach is the distance between the wheel mounting plane and the longitudinal plane of the rim (symmetry). Wheel offset can only have three values: zero, positive and negative. The indicator is indicated by a numeral or alphabetic value. For example, ET40 (mm) is a positive offset, and ET-40 is already negative, so don't get confused and take the minus sign for a dash or a hyphen. The literal meaning is usually denoted by the words OFFSET and DEPORT.

Separately, it should be noted that the greater the departure value, the deeper the car sits in the wheel grooves. And the lower this figure, the more the wheel sticks out of the niche outward. Most car owners are striving to reduce this indicator. In general, it is not entirely correct to deviate from the standard values that were set on the factory conveyor, but sometimes, due to certain circumstances (frequent driving on bumpy or, conversely, perfectly flat roads), you can adjust the offset in the right direction for a more comfortable ride.

› Super test alloy wheels., Not by hitting, so by rolling!We carried out the first, and so far the only, comparative wheel tests - it's scary to remember! - 17 years ago: these were "shock" tests in the MADI laboratory (AR # 15, 1998). And now we are returning to this topic, but at a qualitatively different level: modern stands and new techniques have appeared - and now we will be able to assess not only the impact resistance, but also the fatigue strength of light-alloy wheels. In the offset - 12 samples of 16-inch models produced in Russia, China, Italy and Germany.

We carried out the first, and so far the only, comparative wheel tests - it's scary to remember! - 17 years ago: these were "shock" tests in the MADI laboratory (AR # 15, 1998). And now we are returning to this topic, but at a qualitatively different level: modern stands and new techniques have appeared - and now we will be able to assess not only the impact resistance, but also the fatigue strength of light-alloy wheels. In the offset - 12 samples of 16-inch models produced in Russia, China, Italy and Germany. How much the wheel market has changed! Two-tone, matte, polished, cheaper, more expensive, heavier, lighter ... Choose for every taste and color! Moreover, in theory, you can not worry about strength and reliability: all wheels sold in Russia must have a special certificate, which is issued only if the samples have passed the tests specified in GOST R 50511-93. Or the manufacturer provides certification bodies with the results of tests carried out according to similar methods in other countries, and at the same time, of course, guarantees that the entire batch of products supplied to the market corresponds to the samples that have passed the tests. But this is - in theory, or rather - according to the law. Now we type in the search box "get a certificate for wheel disks"- and Yandex spills out the telephone addresses of dozens of organizations that are ready" in a short time "to issue certificates for compliance with Russian GOSTs and technical regulations Customs Union! Are there really so many laboratories in Russia (by the way, they must also be certified) where you can test rims? Maybe in vain we flew to Krasnoyarsk? Not in vain. Because it was in Krasnoyarsk, on the basis of the K&K plant, that an expensive ZWARP cyclic test bench (from the German Zweiaxialer Radprüfstand - two-axis wheel test bench) of the German company Makra was recently launched.

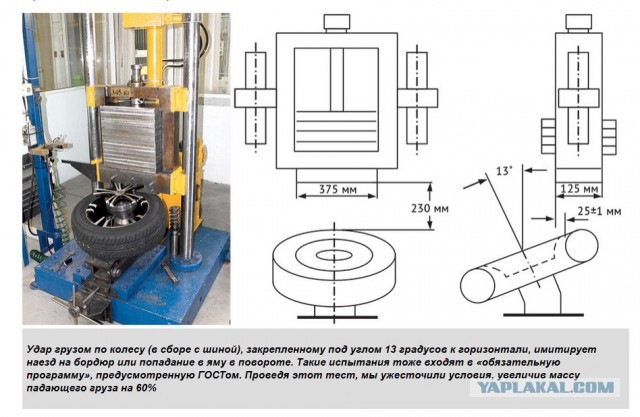

We tested the wheels like this. The running drum of the ZWARP stand spins the wheel assembly with a tire of dimension 215/60 R16 up to a "linear" speed of 120 km / h - and for a run of about 2300 km it undergoes cyclic overloads (for a short time - up to 1800 kgf, which is three times more than stated manufacturers for most of our wheels limit 600 kgf), which simulate the most severe operating conditions: driving an overloaded vehicle, sudden changes of lanes, bumps. Moreover, the so-called load map for our tests was formed on the basis of data obtained while driving on Russian roads. If the wheel successfully passes such tests, then you can be sure that neither fatigue cracks nor destruction will appear in real operation. Another wheel, exactly the same, but without a tire, is also subjected to cyclic loads, but at the stand is simpler. The rim is rigidly attached to the metal table, and a cyclic torque with rotation is applied to the hub part. These tests are already "official", for compliance with GOST R 50511-93, which repeats UNECE rule No. 124. Without destruction and cracks, the wheel must withstand 200 thousand load cycles at a given moment. This is a necessary, but not yet sufficient condition for obtaining a certificate. The Chinese origin of alloy wheels is a reason to be wary, although this does not necessarily indicate poor quality

The third type of test repeats what we were doing 17 years ago in the MADI laboratory - this is a blow to the wheel rim. A complete wheel with a tire inflated to 2.2 bar is attached at an angle of 13 degrees to the horizontal plane - and a weight of 540-648 kg is "dropped" onto it from a height of 230 mm (depending on the load declared by the manufacturer). These are the least time consuming, but perhaps the most compelling tests. Good wheels bend only slightly, tire pressure remains, while bad wheels either "crack at the seams", that is, at the weakest points (as a rule, these are the spokes), or the rim rim breaks, or even the rim itself, and the wheel loses tightness. This means that it does not comply with the aforementioned GOST R 50511-93 - such wheels cannot be sold! We checked this, but then we complicated the task - and on the same stand we carried out additional strikes with a load that exceeded the standard by 60%. It can be considered that this is an imitation of the strongest impact of the wheel on the curb. Of course, “our” 12 wheels are a drop in the sea of the current supply. So the main purpose of these tests is not so much to help in the choice as to understand: is the presence of a certificate a guarantee that the wheels are really safe? By the way, if in those old tests the main competition for Russian wheels was the products of Turkish factories, now half of the 12 samples are “Made in China”.

Please: Chinese Alcasta wheels. Judging by the colorful stickers, they meet every conceivable standard! Here you have the German TUV, and the Japanese JWL and VIA, the Russian PCT (Rostest) and CTP (mark of conformity to the technical regulations of the Customs Union) ... But these "re-certified" wheels did not pass any of our tests. No one! Cracks appeared in the spokes after runs with a cyclic load both on one and on the other test benches, and on impact tests - even without "overloading"! - wheels (new samples, not those that have already been subjected to cyclic loads) are shattered into smithereens! The Chinese LegeArtis and Cross Street wheels failed the tests with almost the same shame. The lighter the wheel, the less durable it tends to be. Exceptions are expensive forged wheels from aluminum alloys or casting from magnesium alloys On the other hand, the Chinese Replay wheels have passed all the tests - and in terms of their fatigue-strength qualities, they turned out to be no worse than pedigree Italian or German models. Chinese wheels Ijitsu and 4GO showed themselves well: they gave slack only in response to cyclic loads at the ZWARP stand, but these tests, we recall, are not included in the mandatory certification program. By the way, serious manufacturers of rims - especially those that supply them for the original equipment of cars - usually check their products at such stands, and often even on a more stringent load map than in our case. I saw K&K wheels spinning in the same laboratory for the "conveyor" configuration of Renault Duster cars, the same tests are being tested for the upcoming Lada Vesta ... losses.

Conspiracy theorists, of course, will immediately figure us out: since the tests were carried out in the workshops of the K&K company, why should they be surprised, his own hand is the master ... But, firstly, we note that both the methods and the equipment itself are certified, that is, the results can be considered "Official". And the specialists here are serious - and they are unlikely to jeopardize their reputation. Secondly, our tests have successfully passed not only K&K wheels, but also, for example, SKAD wheels, although SKAD and K&K are in every sense the closest competitors: the plant where SKAD wheels are produced is located in Divnogorsk, 30 kilometers from Krasnoyarsk ... Do we buy only Russian? Alas. Wheels Tech Line, which are produced in the city of Azov, Rostov region, although they withstood the "certification" and more powerful blows, but under cyclic loads cracked. But the Italian MAK wheels, as well as the German Alutec and Borbet, left no doubt about their highest quality. It is a pity that we had to test samples with a wider rim than those of competing wheels, because we set higher loads on these wheels. Not a single reason to find fault! Except, of course, the price: wheels from Western Europe are one and a half to two times more expensive than Russian or Chinese ones.

And here's another observation. It is clear that the lighter the wheel, the better. Firstly, energy losses for spinning are reduced, secondly, less energy is uselessly converted into heat during braking, and thirdly - and this is, perhaps, the main thing - a lighter wheel provides a longer, and therefore more reliable contact with the supporting surface. Roughly speaking, due to less inertia, it bounces less - and thus provides better vehicle stability. But the game to reduce the mass is worth the candle only under one immutable condition: the wheel must remain strong! A common truth? For Chinese wheel manufacturers LegeArtis and Alcasta - a revelation! Yes, these are lightweight wheels, but they do not take impact, and under cyclic loads cracks appear on the spokes. But since they are sold, then they are certified? Of course, there are lighter and at the same time more durable types of wheels - forged aluminum or magnesium alloy. But they are noticeably more expensive and are now not as popular as the traditional "casting" of aluminum.

It is a pity that corrosion resistance remained behind the scenes of our tests, although this parameter is also included in the list of mandatory tests for compliance with GOST R 50511-93. The wheel is placed in a salt spray chamber, and after 80 hours it should not be covered with "significant corrosion damage" (up to 20% of the wheel surface), and after 240 hours it should not lose strength, which is confirmed by subsequent bench tests. On the eve of the winter season, we will probably return to the topic of wheel corrosion - after all, it is in winter that cars are exposed to the most aggressive “chemical attack”. So, based on the results of the tests, we have two news - and let's start, as usual, with the bad one. The market is littered with bogus-certified wheels. And it doesn't matter if the retail chains are supplied with wheels that do not correspond to the samples that have successfully passed the tests, or the certificates were simply bought, and the tests were not carried out at all. It is important that the certification system at least with regard to wheels, - as we have seen from several examples, this is only a way of earning money for "certifiers". Not only are these "earnings" naturally transferred to the buyers' account, but the main thing is that the same buyers are not guaranteed safety! Although the certification system was introduced precisely in the name of security ... There is no faith in these pieces of paper! Of six Chinese wheels with " compulsory program"Three failed, out of three Russian - one ... And now about the good. First, forewarned means saved. Secondly, half of the wheels tested by us are quite reliable and safe, and all wheels from Germany and Italy passed the test at all without any remarks. But the choice, as we know, is much wider, and therefore - a couple of tips. You should not blindly believe the papers with seals, you should not rely on beautiful stickers. If a store offers you the cheapest wheels and says that they are the best, most reliable, this is a hoax. Modern materials and technologies that are used in the production of light-alloy wheels are costly. The second sign of the quality of an alloy wheel is just the absence of that very lightness. Lightweight wheels of unknown origin are sufficient reason to doubt the durability and refuse to buy. And, finally, it would be nice to find out whether the manufacturer of the wheels you like is also supplying its products to the conveyors of car factories.

I have everything, thanks for your attention, honestly removed from here

2 years

Car wheels are an important component general view vehicle, so the presence of original discs immediately catches the eye. Today, picking up such parts is not at all difficult, because manufacturers have made sure that every car owner has a wide range of choices. How not to make a mistake and buy exactly what you need? To do this, you need to understand the main ones on the market.

Typically, the basic equipment of any vehicle includes steel stamping wheels and road tires. The characteristics of the latter (the so-called "summer" rubber) do not make it possible to use them at low temperatures, therefore, different tires are periodically installed on the same disc: either winter tires, or However, mechanical impact during replacement leads to various damage to the discs, and, in addition to buying new tires, you also have to spend money on repairing or replacing the wheelbase. This fact will lead to the purchase of two different sets of wheels with matching tires for each season.

I must say that steel (stamped) discs are the most popular type today. They are considered representatives of the lower price category, since they are produced using conventional rolled products using stamping, after which the finished product is varnished or primed. Thanks to a fairly simple production technology, their final cost turns out to be two times lower than the cost of cast wheels, but even despite this, not all vehicles leave the assembly line with this type of discs, and light-alloy products come to replace them.

I must say that steel (stamped) discs are the most popular type today. They are considered representatives of the lower price category, since they are produced using conventional rolled products using stamping, after which the finished product is varnished or primed. Thanks to a fairly simple production technology, their final cost turns out to be two times lower than the cost of cast wheels, but even despite this, not all vehicles leave the assembly line with this type of discs, and light-alloy products come to replace them.

In addition to an attractive pricing policy, the advantage of using steel discs is their reliability. So, if a wheel on an light-alloy aluminum base falls into a pit, then most likely it will simply crack, while the stamped disc will only bend, which can be easily fixed at a tire service. Taking the blow, such an element protects the suspension and the vehicle body from serious damage and more expensive repairs. However, there are negative aspects to using stamped steel discs.

Firstly, a sufficiently large weight of the product negatively affects the dynamics of the car (the car accelerates more difficult and slows down worse), and Secondly, the increased unsprung mass of the vehicle adversely affects the functioning of the suspension and the comfort of passengers while driving. Also, one cannot but recall the unpresentable appearance of stamped discs, which is complemented by an increased tendency to corrosion.

So which wheels are better: alloy or steel? Of course, not everyone likes the described features of steel wheels, but many car owners are ready to forgive them some of the shortcomings, especially since in the winter the dynamic properties of the car are not so important, and the low cost is more attractive than the price of alloy wheels.

So which wheels are better: alloy or steel? Of course, not everyone likes the described features of steel wheels, but many car owners are ready to forgive them some of the shortcomings, especially since in the winter the dynamic properties of the car are not so important, and the low cost is more attractive than the price of alloy wheels.

Interesting fact! The very first wheel in the history of mankind is considered a find in the county of Iasi (Romania), which is attributed to the last quarter of the 5th millennium BC. e. It was discovered by the Romanian archaeologist M. Dinu, who found clay wheels from toy carts in one of the Cucuteni settlements. He reported about his find in 1981, and since then we know that the first wheels existed already in the Neolithic era.

Light alloy

Aluminum-based alloys are quite common as a material for the manufacture of wheels (sometimes more expensive magnesium alloys are used). The main advantage of this type of wheels over steel structures (not counting the lower mass) is manufacturing accuracy (runout does not exceed 0.15 mm, while in steel products this value is in the range from 1.5 to 1.8 mm).

In addition, the features of the technology for the production of rims from light alloys make it possible to create a wide variety of shapes that improve the appearance of the vehicle. The design of the discs, as well as the properties of aluminum alloys, contributed to the appearance of wheels with a large rim diameter (17-22 inches) and powerful brakes.

In addition, the features of the technology for the production of rims from light alloys make it possible to create a wide variety of shapes that improve the appearance of the vehicle. The design of the discs, as well as the properties of aluminum alloys, contributed to the appearance of wheels with a large rim diameter (17-22 inches) and powerful brakes.

They are made by pouring molten metal into a mold, followed by grinding the seating surfaces and drilling holes, but this is after cooling the resulting workpiece. Alloy wheels are not as strong as forged options, so the walls are thick enough. Also during the manufacturing process, hidden pores and shells may appear.

It should also be noted that cast aluminum products are 15-30% lighter than steel disks, due to which the unsprung weight of the machine is reduced and fuel consumption is reduced. At the same time, the handling of the car increases and the comfort of movement increases.

Another positive quality of cast aluminum discs is their high resistance to corrosive influences, which is facilitated by the formation of an oxide anticorrosive film on the surface of the disc. What's more, many car manufacturers apply a multi-layer paint finish to the wheels to improve the appearance of the wheel and increase anti-corrosion properties.

Nowadays, you can pick up almost any model of cast aluminum wheels, but all of them will be more susceptible to damage than their steel counterparts. Of course, you can try to repair the wheel, but, as practice shows, it is cheaper to buy right away new disc... That is, the low level of strength is the main disadvantage of cast aluminum wheels.

Nowadays, you can pick up almost any model of cast aluminum wheels, but all of them will be more susceptible to damage than their steel counterparts. Of course, you can try to repair the wheel, but, as practice shows, it is cheaper to buy right away new disc... That is, the low level of strength is the main disadvantage of cast aluminum wheels.

Do you know? Aluminum alloy wheels were first installed on American sports cars in 1964, after which similar wheels appeared on Japanese and Italian public vehicles in 1967.

Forged aluminum wheels

Wrought iron rims made by forging and subsequent machining, which is performed on special lathes (machining centers). Though the cost forged wheels and higher than the cost of cast products, but they are much stronger and lighter than the latter. Moreover, forged wheels have higher anti-corrosion properties, which makes it possible to reduce the requirements for additional surface protection.

If it were not for the high price, based on the complexity of the manufacturing technology, then forged wheels would have long ago ousted all competitors, since few people can compare with most of their characteristics. So, to the low weight and high level of strength (they do not break with strong impacts, like cast ones), it is worth adding quite impressive aerodynamic capabilities of the vehicle, which is especially noticeable when moving at high speeds. That is why forged wheels are so popular among tuning enthusiasts and motor sportsmen.

If it were not for the high price, based on the complexity of the manufacturing technology, then forged wheels would have long ago ousted all competitors, since few people can compare with most of their characteristics. So, to the low weight and high level of strength (they do not break with strong impacts, like cast ones), it is worth adding quite impressive aerodynamic capabilities of the vehicle, which is especially noticeable when moving at high speeds. That is why forged wheels are so popular among tuning enthusiasts and motor sportsmen.

When discussing alloy wheels, special attention should be paid to prefab wheels. They consist of several parts (2-3), fastened together by fixing bolts, which are usually made of titanium or steel. That is, all cast wheels are one-piece structures, and in prefabricated products, the rim and base are connected to each other along the entire perimeter of the wheel, which gives the disc a very unusual look. Experts advise to give preference to products with titanium clamps, as they are not subject to corrosive influences.

The technology for the production of prefabricated discs is based on a combination of methods for creating cast and forged wheels. So, for the manufacture of the rim, the forging technology is most often used, while the base is created by casting. This feature allows to reduce the weight of the wheel by half (the weight of the prefabricated structure is 4-6 kg, and the weight of the cast product is 12 kg).

In addition, a positive feature is the fact that different parts of the assembly wheel can be made of different materials, combining all of them. useful qualities... Basically Italian companies are engaged in the production of prefabricated wheels, but the bolts for them are made in Russia.

Some manufacturers add fake bolts to the solid wheel construction, which serve as a decorative function. In such cases, to distinguish precast wheels from cast models, it is enough to look at the inside of the product. If there are no seams, then you have a solid disc in front of you. Interestingly, wheels with false bolts weigh more than similar models without them.

Some manufacturers add fake bolts to the solid wheel construction, which serve as a decorative function. In such cases, to distinguish precast wheels from cast models, it is enough to look at the inside of the product. If there are no seams, then you have a solid disc in front of you. Interestingly, wheels with false bolts weigh more than similar models without them.

With all its advantages, prefabricated discs also have certain disadvantages, the most noticeable of which is their price.

Interesting to know!The first prefab rims appeared in 1972 and were initially only used on sports cars.

Aluminum or magnesium?

Almost all light-alloy wheels are made on the basis of aluminum, to which some other alloys are added. Thus, the developers are trying to improve the quality of the material. However, there is another option for improving the characteristics of the disc, involving the use of special magnesium alloys. They are much lighter than aluminum ones (the density of magnesium as a metal is much lower), which reduces the final weight of the finished wheel, as well as the unsprung corners of the car.

Light weight and high level strength makes these wheels ideal for sports cars, as the overall weight of the vehicle is reduced, and along with it, the load on the shock absorbers is reduced, making the supercar smoother. These disc models absorb all shocks received during driving and reduce vibration, which has a positive effect on the technical condition of the engine and transmission. In addition, magnesium wheels are highly rigid, which helps to maintain the shape of the tire, thereby reducing tire wear.

The most durable and expensive models are magnesium discs made using forging. These wheels are installed on premium models, as they are the most prestigious option.

The most durable and expensive models are magnesium discs made using forging. These wheels are installed on premium models, as they are the most prestigious option.

However, it should be noted that magnesium discs also have some disadvantages. For example, they can be susceptible to dirt, dust, and moisture, making them less resistant to corrosive influences. Thus, if you do not provide the wheels with proper care, then soon you will have to look for a replacement. It is also important to "protect" the discs in time (preferably immediately after purchase), for which a variety of special varnishes and paints are used to ensure durability, hardness and high surface quality.

Now let's take a closer look at the characteristics of aluminum alloys. Their wide popularity is due to their relatively low cost, beautiful design and high technical performance. Firstly, they are lighter than steel products, which means that the smoothness of the car will be higher, and less fuel is needed. Secondly, thanks to the use the latest technologies when creating cast aluminum rims, the subsequent balancing of the car wheels is also simplified.

If we compare such products with magnesium types, then it should be noted that they are not afraid of debris, dirt and salts, since they have a self-cleaning function, and in order to additionally protect aluminum discs, special agents are applied to them that form an oxide film on the surface. This film spoils the appearance of the disc somewhat, therefore, to add to its attractiveness, manufacturers use paint and varnish coatings. It should also be noted that in the event of deformation, such wheels will be quite difficult to repair, and repairs will cost a pretty penny.

Forged aluminum discs are much stronger than those made by casting, but their price is much higher. So how not to make a mistake in your choice and buy really high-quality products? Which is better to take: magnesium or aluminum wheels? To begin with, it is worthwhile to understand that both types have high thermal conductivity, which helps to reduce the load on the pads and provides cooling to the vehicle.

Forged aluminum discs are much stronger than those made by casting, but their price is much higher. So how not to make a mistake in your choice and buy really high-quality products? Which is better to take: magnesium or aluminum wheels? To begin with, it is worthwhile to understand that both types have high thermal conductivity, which helps to reduce the load on the pads and provides cooling to the vehicle.

Aluminum models are popular with budget and mid-range car owners, and magnesium wheels (especially those created by forging) are more bought by owners of premium and sports cars.

Subscribe to our feeds in

This is due to many serious advantages that give reason to give preference to them over forged and stamped products.

Alloy wheels for your car

Alloy wheels for your car If we talk about what qualities of alloy wheels for cars helped them become so popular, the following factors can be called:

- small mass. This factor significantly affects the driving performance of the car, the wear of all suspension elements, the speed characteristics, and the smoothness of control. Obviously, the less the mass, the better the wheel will perform;

- high thermal conductivity. It guarantees that the auto brake system will not overheat;

- such products are well protected from the effects of rust - they are covered with a special oxide protective layer;

- manufacturing precision. Provides a guarantee of precise fit and balance. If you decide to install alloy wheels on your car, you can be sure: the wear of all suspension elements will be much less than when using forged or cast wheels;

- wide range of designs - such wheels will become another highlight external design your car. There are a huge number of very effective design solutions in the manufacture of alloy wheels.

Alloy wheels are well protected from rust

Alloy wheels are well protected from rust Cast wheels for a car also have certain disadvantages. If you study the reviews of motorists, you can make the following list of negative factors:

- a large number of defects. Casting is carried out in huge volumes, in which it is often not possible to control the quality of products;

- fragile structure. With a strong impact, such products can simply crack;

- alloy wheels are most often not repairable. If damaged, you will need to pick up and purchase new ones;

- piece sale is quite rare - they usually offer to purchase a set for a car.

Characteristics of alloy wheels for cars

When purchasing alloy wheels, it is very important to make the right choice and purchase exactly the option that is suitable for your car.

Therefore, before choosing alloy wheels, you need to make sure that they suit you. For this, a number of parameters are estimated. They will tell you if the selected products are suitable for your car:

- landing width (rim width) is the size between the inner edges of the bead flanges. The correct tire must have the correct fit. Otherwise, the risk of an emergency is very high;

- fit diameter (rim diameter). This is the ring size of the item. It must match the inner diameter of the tire we are installing on it;

Alloy wheel parameters

Alloy wheel parameters - PCD (diameter of the location of the hole for fixation). It depends on how many mounting holes we have, and the distance between them. There are special coefficients that are substituted into the calculation formula - they depend on the number of holes. It is very important here to make sure that this value is valid for your car brand. Only in this case it is possible to correctly center the wheel during installation;

- DIA (bore diameter). Must match the fit on the machine hub. This is necessary for correct alignment. Modern manufacturers often go towards increasing versatility. The landing hole is made larger. In such cases, when installing the wheel, adapter rings are used;

- - this is the distance from the section of the attachment to the central axis of symmetry of the rim. It may not be indicated in the marking, but it is present in the vehicle documentation. How much the suspension is loaded depends on this parameter;

Departure of a rim

Departure of a rim - the number of humps. These bulges serve to ensure that the fixation of the tire is as reliable as possible;

- X factor. The distance between the inner surface of the wheel and the plane of its fixation. Thanks to him, you can put the wheel on a car where there is a braking system out-of-plane.

All of the above parameters give an idea of how to choose alloy wheels for a car so that they fit you and do not cause an emergency or premature wear of the chassis. Almost all of these characteristics are indicated in the product labeling. Looking at it, you can get an idea of how suitable this or that option is for your car.

Wheel rim parameters

Wheel rim parameters Selection criteria when buying alloy wheels

As we found out above, when purchasing wheels for your car, you must determine, based on the parameters given, how the product is suitable for this model. Consider what else you should pay attention to at the time of purchase:

- The make and model of your car. The ideal is a selection of products made specifically for your model. If this is not the case, see that the product fits you in all characteristics and sizes.

- On operating conditions. You should roughly imagine in what conditions you are going to drive. Obviously, you will need more reliable wheels for off-road or wooded terrain than for use on flat roads in urban environments.

- Material for manufacturing. It can be aluminum or magnesium alloy. Each of these metals has advantages and disadvantages. Determine which one is best for you.

- Form and appearance. This is not only the design of the car, but also additional complications, for example, when washing the car.

- Be sure to make sure that the product you are buying has a quality certificate from the manufacturer.

- Don't chase cheap unknown wheels. Give preference to more expensive products from manufacturers with a name.

One of the criteria for choosing a disc is the shape and appearance.

One of the criteria for choosing a disc is the shape and appearance. Advantages of renowned manufacturers

You can often hear that you shouldn't buy discs from unknown manufacturers, but rather choose something more expensive and well-known. Why is it so? After all, you always want to save money, and well-known brands are quite expensive.

The answer is simple: saving on purchase, you can then lose a lot during the period of operation. It is better to choose well-known brands for the following reasons:

- an effective quality control system in serious enterprises makes it less likely to get a marriage;

- high quality of the materials used is an additional guarantee that the product will turn out to be reliable and will meet all requirements and standards;

- every serious manufacturer has its own exclusive production recipes. They improve product quality and performance;

- a cheaper option can behave well on a flat road, but shaking has every chance of leading to a loss of performance;

- coverage on expensive products is more reliable. You don't have to worry about corrosion;

- reputation is a hard thing to earn but very easy to lose. Any manufacturer understands this. Reputable companies have worked for their name for many years and are trying not to lose it. Conclusion

Choosing the right alloy wheels is a guarantee that they will last you a long time and will not pose a hazard on the road.

For a competent assessment of the quality of the product and its compliance with the necessary requirements, marking is used - it contains all the information about the product, its dimensions and parameters.

Any car that has standard metal rims seems gray and ordinary, it feels like it’s missing something. But if you install alloy wheels on the car, then the car is incredibly transformed. The best alloy wheels according to the Mark.guru rating is an opportunity to choose an excellent set of original products for your car.

To choose the best model for a car, take into account certain factors:

- Design... It can be absolutely anything and is selected taking into account personal preferences and wishes.

- The purpose... For a car, this product has a number of functions, including improving the handling of the car, reducing inertia, and improving the functioning of the suspension.

- Diameter... It must match the inner width of the tire. You can choose a larger diameter and use a low profile rubber. In this case, the discs look more solid, but the weight of the wheel increases.

- Mount holes and their diameters(LZ and PCD respectively). If these parameters are incorrectly selected, cast discs will not install. The PCD must meet the prescribed indicators in the manual.

- ET (disk offset)... This is the distance from the attachment point to the plane of symmetry, measured in millimeters. Additional stability and a sporty look to the car are given by wide wheels, but with a minimum outreach. However, this increases the load on the hub bearings, so it is important to take into account the recommendations of the car manufacturers.

- Rubber... When buying products for the available rubber, consider the width of the rim. Narrow or wide will affect tire performance and road contact.

- Quality and right choice ... Only high quality products can guarantee travel safety. It is unrealistic to determine the composition of the metal by eye, and sellers do not always tell the truth. Therefore, for a purchase, it is better to contact specialized salons, which are ready to provide certificates and documents. They will help you make the right choice for your car and tires.

- Manufacturer... Many companies have established themselves as a guarantor High Quality... Often manufacturers or retailers will sell discs with mounting bolts, but these may not fit the machine. Also in production, the DIA (diameter of the hole for the hub) increases, which makes the product universal. You can adjust the size yourself using the centering adapter rings.

If you are looking for a good disc, then check out the Top of popular brands on the market today.

1. Alutec

Our ranking list put Alutec at the top of the list for a number of reasons. The German company has been producing high quality discs since 1996. The manufacturer tries to meet the requirements and desires of customers, offering a large selection, high standard and modern designs. The models embody German quality, which has conquered the markets of Europe and Asia.

Wear resistance and safety appearance models are provided with the use of high-strength varnish.

The average price is 15 thousand rubles.

The advantages of the products are:

- painting;

- quality;

- design;

- price;

- balancing;

- fasteners;

- pothole resistance;

- ease of care.

The downside for some is that they sit tightly on the hub, making them difficult to remove.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

2. DEZENT

The average price of DEZENT models for cars is 12 thousand rubles. For several decades, the German company has been producing discs for machines of various brands and supplying them all over the world.

The advantages are as follows:

- use of technology;

- attention to detail;

- products for almost any brands and models;

- taking into account the requirements of car owners;

- high quality;

- stylish design.

With strong impacts at high speed, even with a sufficiently small hole, dents can appear. In the worst case, the disc may crack or fly apart.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

3. Kosei

For many better disks- these are models at a bargain price. If you also select the product in this way, then the products of the Japanese brand will be a good option, since the average cost is 7 thousand rubles. The company's products are in great demand all over the world.

The Kosei brand is different:

- favorable prices;

- quality products;

- using new technologies;

- the absence of the appearance of microcracks or voids;

- low weight of models;

- high strength;

- rolling the rim.

As the reviews show, it is almost impossible to find flaws in the Kosei brand products. But do not test them for strength on a bad road and at high speed.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

4. LS Wheels

Not expensive, but high quality. The average price is 8,500 thousand rubles. Products of a Taiwanese company, which are in good demand all over the world. Among the advantages are:

- huge selection;

- compliance with international standards;

- modern design solutions;

- profitable price.

LS Wheels owners often complain that the coating begins to peel off over time, the quality is unstable.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

5. OZ Racing

The average cost of OZ Racing wheels is about 75 thousand rubles. and this despite the fact that the cheapest cost about 3,500 thousand rubles.

Peculiarities:

- quality and a large selection;

- large price range;

- development for various models and brands of cars;

- use of the latest technologies in production.

If we talk about the shortcomings, then you need to look for them in the cheapest models. However, in this case it will be rather difficult to find cons.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

6. AEZ

The company has been producing discs for over 20 years. In a short time, the products have become popular and in demand due to a number of advantages:

- usage modern technologies in production;

- high quality of the materials used;

- reliability and durability;

- a large selection of models and prices.

These discs got into the Top not by chance, the products are worthy of respect and attention from the buyers. Considering the range of prices, it is worth noting that the cheapest models have the most disadvantages. But sometimes the most expensive ones also have problems.

Main characteristics:

- diameter R13-R20;

- PCD 3х112-9х108;

- cast, steel, forged.

7. BBS

German products with a long history, the brand is one of the world leaders.

Wheels are often used by German car manufacturers and racers, which confirms their quality.

- three-piece models;

- wide range of prices;

- high quality.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

8. Dotz

Dotz car wheels are characterized by a wide range of prices. The average price is about 40 thousand rubles, and the cheapest will cost 6-7 thousand rubles. The advantage of the brand is that the company initially dealt with discs for cars, which made it possible to achieve high performance in this area.

![]()

It is worth noting:

- high quality;

- big choice;

- interesting design solutions;

- use of high quality materials;

- application of modern technologies.

Given the long history, the knowledge of the company's employees and the production capacity of the brand, it will be difficult to find flaws. At the same time, buyers claim that they simply do not exist.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

9. Enkei

The disks that made it to the Top were selected with the utmost care, which means that we could not miss Enkei. The average price of Japanese products is 10,500 thousand rubles. and they are characterized by the following indicators:

- quality and precision typical of the Japanese;

- high quality materials;

- interesting models;

- use of the latest technologies.

According to the reviews of the owners of Enkei products, they have no shortcomings. However, you should avoid driving fast at high speed in holes. Failure to do so could cause the discs to fly apart and cause a serious accident.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

10. REPLICA (REPLAY)

The company has devoted many years to the production of these discs. During this time, she was able to achieve high performance and offer quality products in different price categories. On average, models cost 17 thousand rubles. They differ in the following characteristics:

- high quality;

- application of the latest technologies in production;

- use of high quality materials.

REPLICA disks got into the Top as one of the best due to their popularity with buyers, but experts say that you need to be careful with them.

First of all, this concerns the weight - it must be identical for the entire set.

Sometimes there are problems with the geometry and quality of the materials used.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

11. IWHEELZ

Inexpensive and varied options, which on average can be purchased at a price of 2.5-3 thousand rubles. Besides favorable price IWHEELZ has a number of other advantages:

- huge selection;

- use of different pricing solutions;

- unique design ideas;

- application of the latest technological advances;

- lightness of products.

The company has been casting various disks for a long time, but given the cost, one should not count on a very high quality.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

12. SKAD

In the ranking of the best discs, SKAD is almost at the very end. And first of all, this is due to their cost, which directly affects the quality of the final product. On average, the price is 5 thousand rubles. According to the company, the products differ in the following indicators:

- the use of only high-quality and durable materials;

- a large selection of design solutions;

- the use of different colors;

- lightness and strength;

There are also disadvantages, and they are mainly associated with the appearance of scratches and microcracks on the coating of products.

Main characteristics:

- diameter R13-R22;

- PCD 3х112-9х108;

- cast, steel, forged.

13. K&K (KIK)

Inexpensive and reliable - this is K&K. Products will cost an average of 4.5 thousand rubles. The concern is one of the world leaders in the production of discs, which are in great demand due to the following parameters:

- high reliability and German quality;

- a huge selection of design solutions;

- many years of production experience;

- application of the latest technologies.

It is incredibly difficult to find flaws in K&K, and this despite the fact that their products are chosen by every fourth car owner.

Main characteristics:

- diameter R13-R24;

- PCD 3х112-9х108;

- cast, steel, forged.

It is possible to select high-quality and original discs in any price category. However, the higher the price, the better quality and characteristics. We tried to include in the Top best discs for every wallet and taste. The rating also took into account design ideas and color solutions.

Customizable software

Customizable software Windows 8 will return the start button

Windows 8 will return the start button Installing Skype on a computer (step by step instructions)

Installing Skype on a computer (step by step instructions)